Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

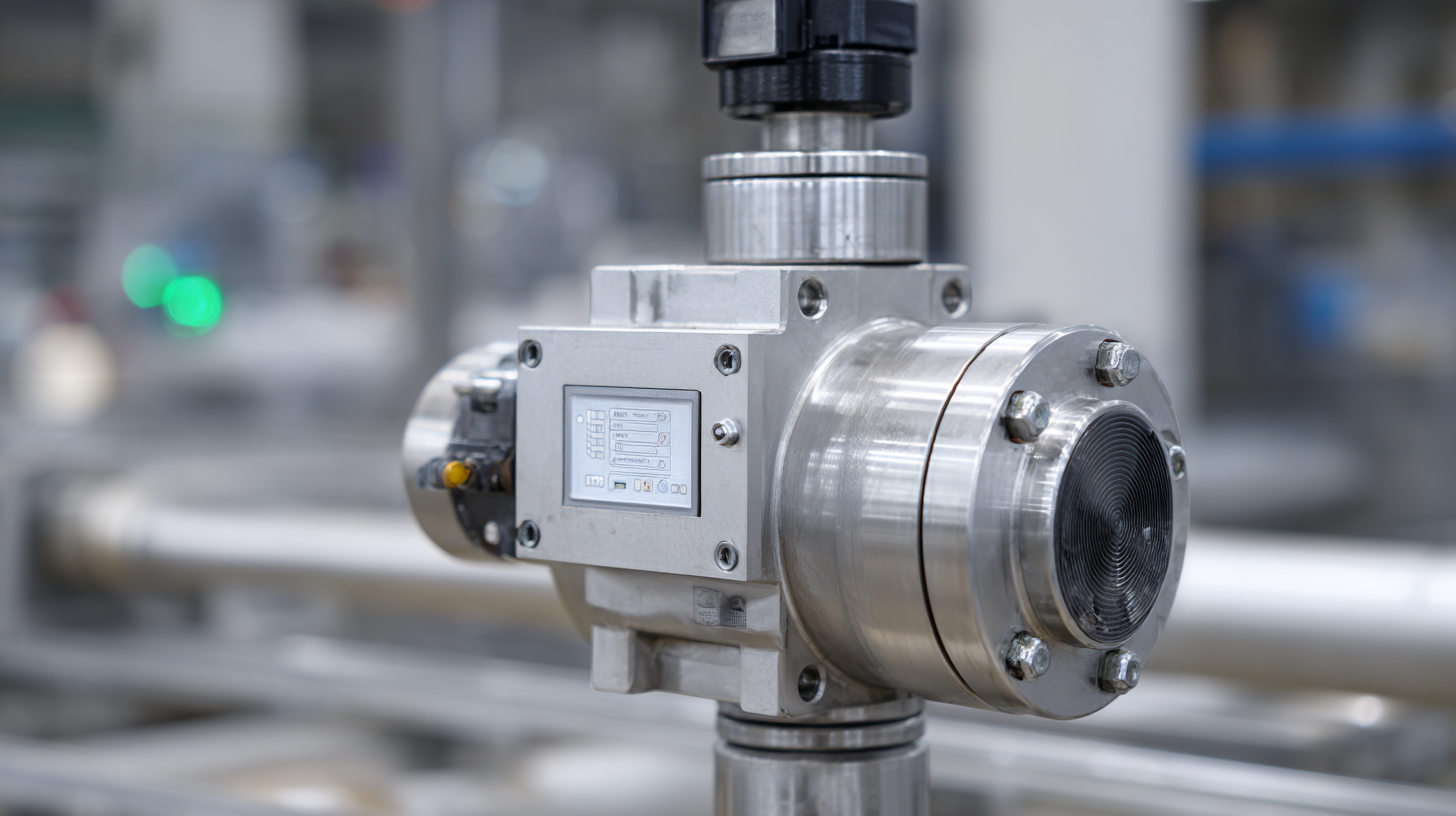

In the ever-evolving landscape of industrial automation, the quest for heightened efficiency has led to the integration of advanced technologies that streamline operations and enhance performance. Among these innovations, the ball valve actuator stands out as a crucial component that is revolutionizing the way industries manage fluid control systems. By automating the opening and closing of ball valves, these actuators not only ensure precise flow regulation but also significantly reduce manual labor, minimize downtime, and improve safety in hazardous environments.

This article delves into the myriad ways in which ball valve actuators are transforming industrial automation, highlighting best practices for implementation to maximize their potential. Whether you are looking to upgrade existing systems or considering an initial investment in automated solutions, understanding the capabilities of ball valve actuators is essential for unlocking unparalleled efficiency in your operations.

The Growing Demand for Automation in Industrial Processes

The growing demand for automation in industrial processes is driving significant advancements in various sectors, particularly in the realm of industrial automation. By 2029, the global industrial automation market is projected to escalate from $205.86 billion in 2022 to $395.09 billion, with a compound annual growth rate (CAGR) of 9.8%. This rapid expansion reflects an increasing reliance on automated systems to enhance operational efficiency, reduce costs, and improve production quality across industries.

Moreover, the rise of wireless industrial IoT sensors is set to revolutionize data collection and analysis within automation frameworks. The market for these sensors is expected to reach $7.973 billion by 2025 and grow to $21.498 billion by 2033, showcasing a remarkable CAGR of 13.2%. As companies integrate advanced technologies like IoT, big data, and artificial intelligence into their processes, the landscape of industrial automation will evolve, further solidifying its integral role in modern manufacturing environments.

Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

| Feature | Description | Benefits | Industry Applications |

|---|---|---|---|

| Precision Control | Allows for accurate and reliable operation of valves in various processes. | Enhanced process efficiency and reduced wastage. | Chemical, Oil & Gas, Water Treatment |

| Automation Integration | Easily integrates with various industrial automation systems. | Seamless operations and reduced manual intervention. | Manufacturing, Food & Beverage, Pharmaceuticals |

| Energy Efficiency | Designed to minimize energy usage during operation. | Lower operational costs and sustainable practices. | Power Generation, HVAC, Pulp & Paper |

| Durability | Constructed from robust materials to withstand harsh environments. | Longer lifespan and reduced maintenance requirements. | Mining, Marine, Waste Management |

| Remote Operation | Can be operated remotely via control systems. | Increased safety and operational flexibility. | Utilities, Transportation, Construction |

Impact of Ball Valve Actuators on Operational Efficiency Metrics

Ball valve actuators play a pivotal role in enhancing operational efficiency within industrial automation systems. By providing rapid and precise control over fluid flow, these actuators reduce response times during critical processes. This agility leads to optimized production cycles and minimizes downtime, which is essential in high-demand environments. As industries increasingly rely on automation, the seamless integration of ball valve actuators into existing systems not only streamlines operations but also lowers energy consumption, significantly contributing to cost savings.

Moreover, the impact of ball valve actuators on operational efficiency metrics can be quantified through improved reliability and consistency. Their robust design ensures minimal wear and tear, leading to longer service intervals and reduced maintenance costs. This reliability enhances overall system performance and allows for more predictable output, thus aiding in fulfilling production targets. As automation continues to evolve, the adoption of advanced ball valve actuators is likely to be a determining factor in achieving higher efficiency levels and maintaining competitive advantages in the industrial sector.

Key Industry Statistics Highlighting Cost Savings with Automated Solutions

Automated solutions in industrial settings have demonstrated significant cost savings, driven by the efficiency enhancements brought forth by technologies such as ball valve actuators. According to recent statistics, businesses integrating automated systems report an average reduction of operational costs by 30%, primarily attributed to decreased labor expenses and enhanced process accuracy. By minimizing human intervention, these systems allow for continuous operation and reduced downtime, which directly translates to higher productivity.

Moreover, the investment in automated solutions like ball valve actuators leads to a marked decrease in maintenance costs. With improved reliability and the ability to perform real-time diagnostics, these actuators proactively address issues before they escalate into costly repairs. Industry reports indicate that companies adopting such technologies experience a 40% decrease in maintenance expenditures, highlighting the financial advantages of transitioning to automated systems. These statistics underscore not only the immediate cost benefits but also the long-term financial viability of investing in automation within industrial automation systems.

Comparative Analysis of Traditional vs. Actuated Ball Valves in Automation

The impact of ball valve actuators on industrial automation systems is profound, particularly when comparing traditional ball valves to actuated versions. Traditional ball valves, primarily operated manually, often present limitations in speed and efficiency, especially in large-scale operations where rapid response times are critical. Manual operation can lead to delays, increased labor costs, and potential safety hazards, making them less suitable for modern automated environments that demand precision and reliability.

The impact of ball valve actuators on industrial automation systems is profound, particularly when comparing traditional ball valves to actuated versions. Traditional ball valves, primarily operated manually, often present limitations in speed and efficiency, especially in large-scale operations where rapid response times are critical. Manual operation can lead to delays, increased labor costs, and potential safety hazards, making them less suitable for modern automated environments that demand precision and reliability.

In contrast, actuated ball valves enhance operational efficiency by allowing for automatic control. These valves can be integrated into process control systems, enabling real-time adjustments based on system demands. The incorporation of actuators facilitates quicker valve operation, reduces human error, and allows for remote monitoring and control. As industries seek to optimize productivity, the shift toward actuated ball valves emerges as a vital strategy, demonstrating significant improvements in system responsiveness, energy efficiency, and overall process reliability.

Future Trends: Integration of IoT and Smart Technologies in Valve Actuation

The integration of the Internet of Things (IoT) and smart technologies is transforming the landscape of valve actuation within industrial automation systems. As manufacturers seek to enhance operational efficiency, smart ball valve actuators equipped with IoT connectivity enable real-time monitoring and remote control. These actuators gather data on performance metrics and system statuses, allowing for predictive maintenance and reducing downtime. By embedding sensors and communication protocols, facilities can access vital insights into the functioning of their valve systems, leading to optimized processes and improved reliability.

Moreover, the future of valve actuation will see an increase in the adoption of artificial intelligence (AI) and machine learning algorithms. These technologies will enhance the decision-making capabilities of smart actuators, allowing them to learn from historical data and adjust their operations automatically. As industries move toward increased automation and digitization, smart ball valve actuators will play a crucial role in creating interconnected systems that not only streamline workflows but also enhance overall productivity. This synergy of smart technologies and traditional industrial components marks a significant shift in how valve actuation is approached, promising innovations that will redefine operational standards in the coming years.

Impact of IoT Integration on Valve Actuators in Industrial Automation

Related Posts

-

Understanding the Importance of Pneumatic Ball Valves in Modern Industrial Applications

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

How to Choose the Right Industrial Valves for Your Manufacturing Needs

-

Understanding the Role of Check Valves in Fluid Control Systems for Enhanced Efficiency

-

Future Trends in Metering Valve Technology at 2025 China Import and Export Fair

-

Mastering Ball Valve Selection: A Comprehensive Tutorial for Optimal Flow Control in Industrial Applications