2025 Top 10 PTFE Valves for Chemical Processing with 30 Percent Improved Durability

In the ever-evolving landscape of chemical processing, the demand for advanced materials and components is crucial to enhance efficiency and durability. Among these, the PTFE valve has emerged as a leading solution, celebrated for its remarkable resistance to corrosive chemicals and exceptional thermal stability. As industries seek to optimize their operations, understanding the latest advancements in PTFE valve technology becomes imperative.

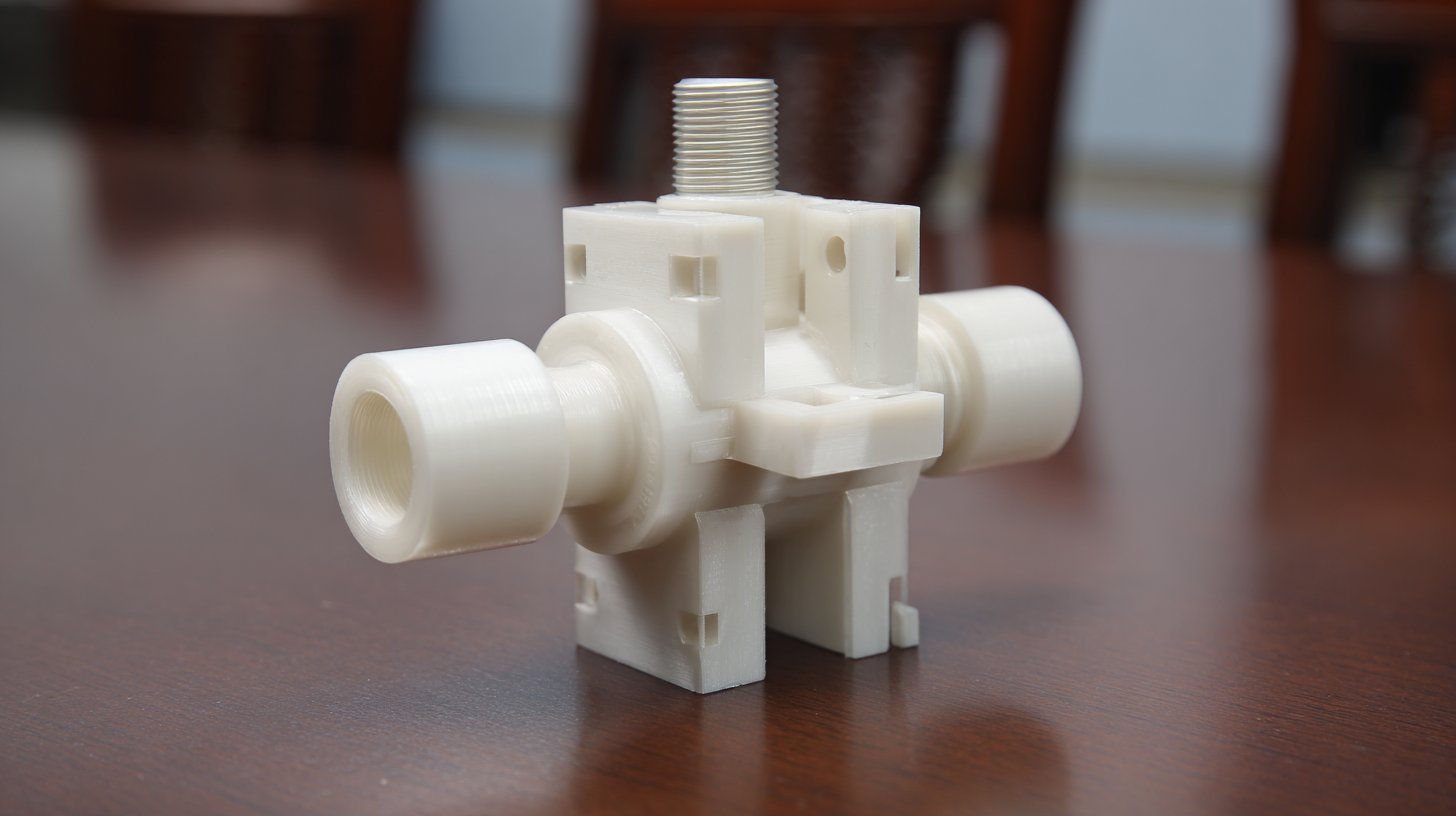

This article delves into the top 10 PTFE valves for chemical processing in 2025, highlighting innovations that promise 30 percent improved durability. By focusing on these cutting-edge designs, we aim to provide insights into how these valves can significantly enhance system performance while minimizing maintenance costs. Whether you're an industry veteran or new to the field, this guide will equip you with essential tips to select the most suitable PTFE valve for your specific applications, ensuring safety and reliability in your chemical processing endeavors.

2025 Innovations in PTFE Valve Design for Enhanced Chemical Resistance

In 2025, the landscape of PTFE valves for chemical processing is reshaping to prioritize durability and enhanced chemical resistance. Recent innovations in PTFE valve design have introduced cutting-edge materials and engineering techniques that significantly improve their performance. These advancements ensure that PTFE valves can withstand extreme conditions, including harsh chemicals and elevated temperatures, ultimately extending their lifespan and reliability in critical applications.

When selecting PTFE valves for your operations, consider the following tips: First, always verify the compatibility of the valve material with the specific chemicals you are handling. Even minor discrepancies can lead to failures. Second, pay attention to the design features that enhance sealing capabilities, as this can prevent leaks and protect your processes. Lastly, evaluate the manufacturer's warranty and support services, as these can be indicative of the valve’s quality and the company’s commitment to customer satisfaction.

The new design features in these valves, including improved sealing technology and reinforced structures, play a crucial role in minimizing downtime and maintenance costs. Investing in advanced PTFE valves not only safeguards your operations but also boosts efficiency, making them an essential component of modern chemical processing.

Key Features of Top 10 PTFE Valves for Chemical Processing Applications

When selecting PTFE valves for chemical processing applications, several key features can significantly enhance both performance and durability. The top ten valves in 2025 are engineered with advanced materials that resist corrosion and chemical degradation, ensuring a longer lifespan even in harsh environments. These valves benefit from innovative sealing technologies that prevent leaks and minimize maintenance, making them ideal for the rigorous demands of chemical processing.

**Tips:** When evaluating PTFE valves, consider the temperature and pressure ratings specific to your applications, as well as the compatibility of the valve materials with the chemicals being handled. Proper installation is crucial to maintain the duration and effectiveness of the valves, so consult installation guidelines provided by manufacturers for best practices.

Additionally, look for features such as easy-to-operate actuators and automated control options. These advancements not only simplify the operation but also contribute to improved process efficiency. Moreover, consider valves with a unified design, as this can help streamline replacement parts and reduce downtime in your operations.

2025 Top 10 PTFE Valves for Chemical Processing with 30 Percent Improved Durability

| Valve Model | Size (inches) | Max Pressure (psi) | Temperature Range (°F) | Durability Improvement (%) | Key Features |

|---|---|---|---|---|---|

| Model A | 1 | 150 | -40 to 200 | 30 | Corrosion Resistant, Easy Maintenance |

| Model B | 2 | 200 | -20 to 250 | 30 | Low Resistance, High Flow Rate |

| Model C | 1.5 | 180 | -40 to 220 | 30 | Self-Cleaning, Anti-Tamper Design |

| Model D | 3 | 300 | 0 to 150 | 30 | Easy Installation, Leak Proof |

| Model E | 2.5 | 250 | -30 to 260 | 30 | Chemical Resistant, Modular Design |

| Model F | 4 | 350 | -20 to 280 | 30 | High Strength, Non-Stick Surface |

| Model G | 6 | 400 | 0 to 300 | 30 | Fire Resistant, High Performance |

| Model H | 5 | 300 | -10 to 230 | 30 | Durable Sealing, Wide Compatibility |

| Model I | 3.5 | 230 | -30 to 260 | 30 | High Efficiency, Low Maintenance |

| Model J | 4.5 | 360 | 0 to 300 | 30 | Robust Design, Excellent Flow Control |

Comparative Analysis: Durability Improvements Across Leading PTFE Valve Models

In the competitive landscape of chemical processing, the quest for enhanced durability in PTFE valves has driven significant innovations. Recent developments have showcased a range of models that promise up to 30 percent improved durability compared to their predecessors. Leading manufacturers have employed advanced materials and engineering techniques, resulting in valves that not only resist corrosive substances but also maintain integrity under high-pressure conditions.

Comparative analysis across these top 10 PTFE valve models reveals notable variations in performance. Some brands have incorporated reinforced PTFE blends, while others utilize specialized coatings to further enhance lifespan. Testing has shown that models featuring these innovations not only outperform traditional designs but also offer:

- Longer maintenance intervals

- Reduced operational costs

As chemical processing plants prioritize efficiency and safety, selecting a durable PTFE valve becomes essential for optimizing performance and minimizing downtime.

Applications and Performance Metrics of 2025's Best PTFE Valves in Harsh Environments

In 2025, the advancements in PTFE valve technology have rendered these components essential in chemical processing, particularly within harsh environments. PTFE valves are lauded for their exceptional resistance to corrosive chemicals, high temperature tolerance, and the reduced friction they provide in flow control systems. These improvements allow for not only operational efficiency but also a significant reduction in maintenance costs, as the new designs withstand wear and tear far better than previous iterations.

Performance metrics of the top PTFE valves include enhanced leak-proof capabilities, higher pressure tolerances, and extended lifespan. Manufacturers have integrated innovative sealing technologies that ensure optimal functionality even under extreme conditions. Furthermore, the new valve designs incorporate improved flow characteristics, resulting in noticeable energy savings during operation. Users can expect reliable performance, achieving operational targets while maintaining safety standards in the demanding environments typical of the chemical processing industry.

Future Trends in PTFE Valves: What's Next for Chemical Processing Technology

As the chemical processing industry continues to evolve, the future trends in PTFE valves are becoming increasingly vital for maintaining operational excellence. According to a recent report by the Chemical Engineering Research Journal, the global demand for PTFE valves is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by their superior corrosion resistance and ability to handle aggressive chemicals. This growth underscores the need for advancements in material science that enhance the durability and efficiency of PTFE valves.

Furthermore, innovations in PTFE material formulations are leading to enhanced performance characteristics, with recent studies indicating that new composites can offer up to 30% improved durability compared to traditional PTFE. This increased longevity not only reduces the frequency of replacements but also minimizes downtime, contributing to overall cost savings in chemical processing operations. As industries seek to adhere to stricter environmental regulations and improve sustainability practices, the development of eco-friendly PTFE alternatives is also on the horizon, promising to reshape the landscape of chemical processing technology in the coming years.

2025 Top 10 PTFE Valves Durability Comparison

This chart illustrates the predicted durability improvements of the top 10 PTFE valves for chemical processing in 2025, showcasing a 30% enhancement over previous models.

Related Posts

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

Unmatched Excellence in PTFE Lined Check Valves: Crafted in China, Delivered Worldwide

-

Understanding the Role of Check Valves in Fluid Control Systems for Enhanced Efficiency

-

Ultimate Guide to Selecting the Right Industrial Valves for Your Applications

-

Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

-

Mastering Ball Valve Selection: A Comprehensive Tutorial for Optimal Flow Control in Industrial Applications