Understanding the Mechanisms and Benefits of Ball Check Valves in Modern Applications

The ball check valve has emerged as an essential component in various modern industrial applications, providing reliable performance through its unique design. According to a report by Global Market Insights, the market for check valves is expected to surpass $10 billion by 2026, driven by the rising demand for efficient flow control solutions in sectors such as oil and gas, water treatment, and HVAC systems. The ball check valve, in particular, offers significant advantages over other types of check valves due to its ability to prevent backflow and maintain accurate flow direction, all while operating with minimal pressure drop.

As industries strive for enhanced efficiency and sustainability, the incorporation of ball check valves has proven beneficial. Research indicates that these valves can reduce energy consumption significantly, which is a crucial factor in today’s environmentally-conscious market. Moreover, their robust construction and long service life contribute to lower maintenance and replacement costs, making them a preferred choice for engineers and facility managers alike. Understanding the mechanisms and benefits of ball check valves is vital for harnessing their full potential and ensuring optimal system performance in various applications.

Key Mechanisms of Ball Check Valves: How They Function in Fluid Control Systems

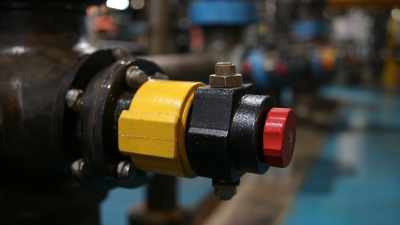

Ball check valves are essential components in fluid control systems, designed to allow fluid to flow in one direction while preventing backflow. The fundamental mechanism involves a spherical ball that rests in a seat within the valve body. When fluid pressure on the inlet side exceeds that in the opposite direction, the ball is pushed away from the seat, allowing fluid to pass through. Conversely, when the inlet pressure drops, gravity or reverse pressure forces the ball back into the seat, creating a seal that prevents any backward flow. This simple yet effective mechanism ensures optimal performance in various applications.

In modern engineering, ball check valves are prized for their reliability and low maintenance requirements. They are commonly used in wastewater treatment, drainage systems, and in various pumping applications, where backflow can lead to significant operational issues. Their design minimizes turbulence and pressure loss, contributing to more efficient fluid transport. The materials used in manufacturing these valves can withstand harsh environmental conditions, making them suitable for both industrial and residential applications. Understanding these mechanisms is crucial for engineers and designers aiming to implement effective fluid control solutions.

Understanding the Mechanisms and Benefits of Ball Check Valves in Modern Applications

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Material | Typically metal, plastic, or rubber | Durability and Chemical Resistance | Pipelines, Water Systems |

| Size | Available in various sizes, from 1/2" to 8" | Versatility for Different Systems | HVAC, Industrial Equipment |

| Operation Mechanism | Utilizes a ball that moves with fluid flow | Prevents backflow effectively | Wastewater Management, Chemical Processing |

| Pressure Rating | Varies by size; common ratings from 150 to 300 PSI | Suitable for high-pressure systems | Oil & Gas Industry, Fire Protection |

| Installation Type | Can be installed in horizontal or vertical positions | Flexible installation | Water Treatment, Plumbing Systems |

System Benefits: Enhancing Safety and Efficiency with Ball Check Valves

Ball check valves play a crucial role in enhancing the safety and efficiency of various modern applications, particularly in fluid management systems. These valves operate on a simple yet effective mechanism where a movable ball prevents backflow by sealing against the valve body when the fluid reverses direction. According to a recent industry report by Research and Markets, the global market for ball valves is projected to reach $13.9 billion by 2026, underscoring their importance in sectors such as oil and gas, water treatment, and chemical processing.

One of the significant benefits of ball check valves is their ability to maintain system integrity. By preventing backflow, they help to avoid contamination in systems that handle sensitive materials. A study published in the Journal of Flow Control Tech highlighted that using ball check valves can reduce potential leak points by up to 60%, leading to a safer operational environment. Furthermore, their robust design minimizes maintenance requirements, allowing systems to operate continuously at peak efficiency.

Tips: When selecting ball check valves, consider their size and material to ensure compatibility with your specific application. Regular inspections can further enhance performance and longevity, reducing the likelihood of unexpected failures.

Comparative Analysis: Ball Check Valves vs. Traditional Check Valves in Various Applications

In recent years, the utilization of ball check valves has gained momentum across various industrial applications when compared to traditional check valves. A report by the Flow Control Institute highlights that ball check valves can offer a reduced pressure drop of up to 30% compared to conventional designs. This efficiency becomes critical in ensuring optimal fluid flow while minimizing energy consumption in pumping systems. The design of ball check valves allows for a tighter seal, reducing the risk of leaking, which is often a significant disadvantage in traditional valves.

Moreover, the longevity and reliability of ball check valves present an operational advantage. According to a study conducted by the Valve Manufacturers Association, ball check valves can typically handle higher operational pressures and temperatures—up to 500 psi and 300°F—making them suitable for more demanding environments. This robustness reduces maintenance costs and downtime, further propelling their adoption in industries such as oil and gas, water treatment, and chemical processing. While traditional check valves remain relevant, the enhanced performance metrics of ball check valves are increasingly being recognized as a means to optimize both operational efficiency and reliability across numerous applications.

Comparative Analysis of Ball Check Valves vs. Traditional Check Valves in Various Applications

Installation and Maintenance Best Practices for Optimal Ball Check Valve Performance

Ball check valves are essential components in various modern applications, known for their reliability and efficiency in allowing fluid flow in one direction while preventing backflow. To ensure optimal performance and longevity of these valves, adhering to best practices during installation and maintenance is crucial. According to a report from the American Society of Mechanical Engineers (ASME), improper installation can lead to a 30% decrease in efficiency, underscoring the importance of correct procedures.

When installing a ball check valve, it’s crucial to ensure that the valve is oriented correctly in the pipeline. This can be verified by checking the manufacturer's specification for flow direction. Additionally, maintaining a clean and clear area around the valve during installation can prevent debris from entering the system, which might compromise functionality.

**Tips:** Regular maintenance should include inspecting the valve for any signs of wear or corrosion, as these can significantly affect performance. Schedule routine inspections every six months, and consider replacing seals or O-rings if they show signs of degradation. Timely maintenance can boost the lifespan of ball check valves by up to 25%, according to industry studies.

Future Trends: Innovations in Ball Check Valve Technology for Industrial Applications

The advancements in ball check valve technology are rapidly shaping the future of industrial applications. As industries become increasingly automated and demand for efficiency rises, innovations are being integrated into the design and functionality of these essential components. New materials, such as lightweight composites and advanced metals, are being utilized to enhance durability and resistance to corrosive environments, which is crucial for industries like chemicals and oil and gas.

Moreover, the implementation of smart technologies is revolutionizing the way ball check valves operate. Sensors and IoT connectivity allow for real-time monitoring of valve performance, leading to predictive maintenance and reduced downtime. These innovations not only improve operational efficiency but also drive down costs associated with system failures and maintenance. As manufacturers focus on sustainability, eco-friendly designs and energy-efficient solutions are becoming standard, further highlighting the importance of ball check valves in meeting modern industrial demands.

Related Posts

-

How to Optimize Your Pipeline Efficiency with Ball Check Valves: Best Practices and Insights

-

Understanding the Functionality of Ball Check Valves in Fluid Control Systems

-

Understanding the Benefits of Ball Check Valves in Industrial Applications: A Comprehensive Guide

-

Understanding the Benefits and Applications of Lockable Ball Valves in Industrial Settings

-

Mastering Ball Valve Selection: A Comprehensive Tutorial for Optimal Flow Control in Industrial Applications

-

How to Choose the Right Ball Check Valve for Your Industrial Applications