Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One

In the ever-evolving landscape of industrial automation, choosing the right actuator valve can significantly enhance operational efficiency and system reliability. According to a report by MarketsandMarkets, the global actuator market is projected to reach $75.6 billion by 2025, highlighting the growing importance of these components in various sectors, including oil and gas, water management, and manufacturing. Understanding industry standards is crucial as they dictate the quality and performance of actuator valves. Adhering to these standards not only ensures compliance but also helps in selecting valves that meet specific application requirements.

This ultimate guide will delve into the essential factors to consider when choosing an actuator valve, backed by industry insights and best practices, enabling businesses to make informed decisions and optimize their processes.

Understanding Actuator Valve Types: A Comprehensive Guide

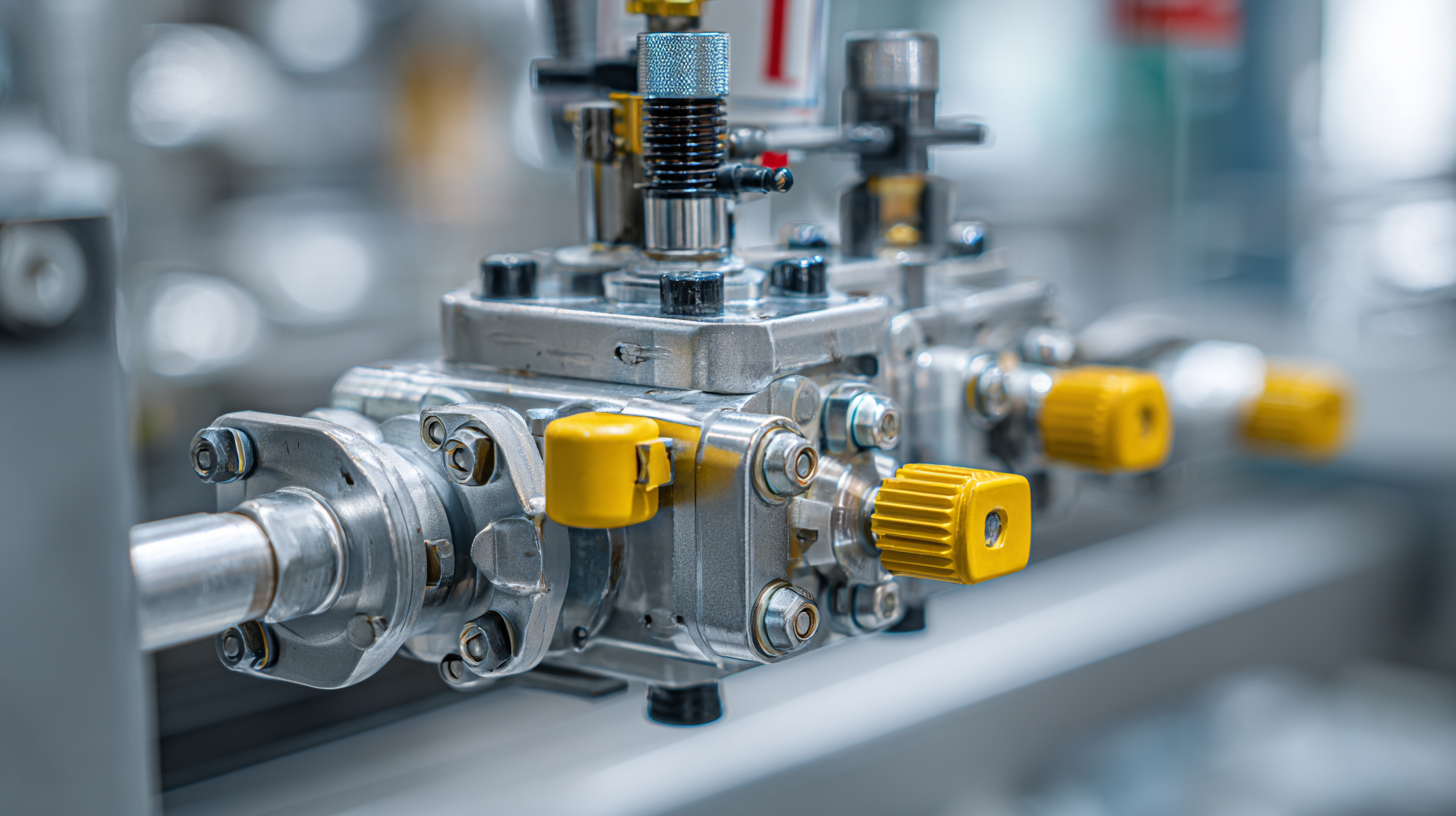

In the world of actuator valves, understanding the various types available is crucial for ensuring optimal performance in different applications. Actuator valves are essential components in many industrial systems, providing precise control over fluid flow. The main types include electric, pneumatic, and hydraulic actuators, each with their own advantages and suitable use cases. For instance, electric actuators are often preferred for applications requiring high precision, while pneumatic options are valued for their speed and efficiency in dynamic environments.

When selecting the right actuator valve, it is essential to consider factors like operating environment, response time, and compatibility with the fluid being controlled. Industry reports indicate that the Marine Valve Market is projected to grow from USD 4.2 billion in 2024 to USD 6.1 billion by 2033, illustrating the increasing demand for advanced valve technologies in various sectors. This trend highlights the importance of choosing actuator valves that not only meet current industry standards but also cater to evolving market needs.

**Tips:** Always evaluate the specific requirements of your application before making a decision. Consider consulting with industry experts to gain insights into the latest innovations and standards that may affect your choice. Regular maintenance and performance monitoring of actuator valves will also ensure long-term efficiency and reliability in your operations.

Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One - Understanding Actuator Valve Types: A Comprehensive Guide

| Actuator Valve Type | Operating Principle | Common Applications | Pros | Cons |

|---|---|---|---|---|

| Electric Actuator | Uses electric power to operate | Water treatment, HVAC systems | High precision, easy integration | Dependent on power supply |

| Pneumatic Actuator | Uses compressed air to operate | Manufacturing, food processing | Fast response, suitable for harsh conditions | Requires air supply and filtration |

| Hydraulic Actuator | Uses hydraulic fluid pressure | Heavy machinery, industrial automation | High power density, robust design | Complex system, leakage potential |

| Smart Actuator | Integrated with IoT technologies | Energy management, smart buildings | Real-time monitoring, automation | Higher cost, requires network |

| Manual Actuator | Operated by hand | Water valves, HVAC systems | Low cost, simple design | Labor-intensive, not suitable for remote operation |

Key Industry Standards Every Engineer Should Know

In the realm of actuator valves, understanding key industry standards is vital for engineers looking to ensure safety, efficiency, and compliance in their projects. One of the most significant standards to be familiar with is the ISO 15761, which specifies requirements for all types of valves, including actuator-operated models. This standard not only outlines testing and performance criteria but also provides guidelines for materials and design, which can impact the overall lifespan and reliability of the valves.

Another important standard is the API 602, which addresses the specifications for gate valves in general service, applicable to many actuator valves. As outlined in a 2022 industry report by the Valve Manufacturers Association, adherence to these standards is crucial, as it has been shown that compliant valves can reduce maintenance needs by up to 30%. This emphasizes the importance of engineers selecting actuator valves that meet established standards to not only enhance operational efficiency but also to minimize long-term operational costs.

Additionally, the ASME B16.34 standard governs the requirements for valves in pressure service. Compliance with this standard ensures that the actuators can withstand varying pressure conditions, which is critical in industries like oil and gas, where pressure fluctuations can significantly compromise safety. By equipping themselves with knowledge of these standards, engineers can make informed decisions that align with industry best practices and regulatory frameworks.

Factors to Consider When Selecting the Right Actuator Valve

When selecting the right actuator valve, several key factors come into play that can significantly impact both efficiency and safety in industrial applications. One critical consideration is the type of actuator—electric, pneumatic, or hydraulic—each having its unique advantages. For instance, electric actuators are increasingly favored for their precision in linear motion and reduced emissions during process control, proving to be viable alternatives to traditional pneumatic systems. This aligns with recent advancements in automation, where the push towards environmentally friendly solutions is gaining momentum.

Moreover, the choice between these actuators may depend on the specific operational conditions. Factors such as load requirements, the speed of actuation, and the operational environment should be meticulously evaluated. The recent trends in converting hydraulic systems to electric solutions highlight the importance of accurately assessing loads and forces for successful integration. As industries lean towards more automated and energy-efficient systems, understanding the standards and capabilities of each type of actuator valve becomes essential in making informed choices that enhance productivity and safety in the workplace.

Top Applications for Actuator Valves in Various Industries

Actuator valves play a crucial role in various industries, particularly in the growing field of robotics. Recent advancements, such as the development of a topology-optimized compliant actuator for soft robotic grippers and walking robots, highlight how actuator technology is transforming robotic applications. These innovative actuators enable greater flexibility and precision, making them essential in manufacturing and automation processes.

Tips for choosing the right actuator valve include understanding the specific requirements of your application. Consider factors such as the required torque, speed, and adaptability to different environments. For instance, in robotics, responsive actuator valves are necessary to ensure that robotic movements are fluid and efficient.

Additionally, staying abreast of industry standards is vital for ensuring compatibility and performance. In sectors like robotics, where new applications and technologies emerge rapidly, selecting actuator valves that meet recognized standards can lead to improved performance and reliability in operations. This attention to detail will help in maximizing the capabilities of robotic systems across various applications.

Expert Tips for Ensuring Optimal Performance of Actuator Valves

When selecting actuator valves, understanding industry standards is crucial to ensure optimal performance. These standards define the specifications that the valves must meet to operate effectively within various HVAC systems. Key factors to consider include the valve's material, size, pressure rating, and the type of control mechanism employed. Knowing these standards not only streamlines the selection process but also enhances reliability and efficiency in water distribution across heating and cooling systems.

To guarantee optimal performance, it is essential to assess the actuator valve's compatibility with existing systems. Conduct thorough evaluations of the system dynamics and the specific requirements of the environment in which the valve will be installed. Implementing regular maintenance and monitoring practices can significantly extend the lifespan and functionality of actuator valves. Moreover, utilizing advancements in technology, like smart actuators, can facilitate remote control and adaptive management, further improving the overall system performance while ensuring that energy consumption is minimized.