Understanding the Importance of Pneumatic Ball Valves in Modern Industrial Applications

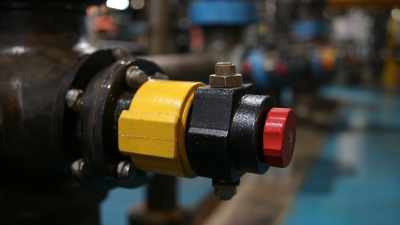

In today's fast-paced industrial landscape, the efficiency and reliability of fluid control systems are paramount for achieving optimal performance. One crucial component that has gained significant prominence is the pneumatic ball valve. These valves not only offer precise control over the flow of gases and liquids but also feature rapid response capabilities that are essential in various applications, ranging from manufacturing to chemical processing. Understanding the importance of pneumatic ball valves in modern industrial applications is vital for engineers and technicians seeking to enhance operational efficiency. This article will delve into the key advantages, installation guidelines, and maintenance tips related to pneumatic ball valves, equipping professionals with the knowledge needed to make informed decisions about integrating these essential components into their systems.

Importance of Pneumatic Ball Valves in Streamlining Industrial Processes

Pneumatic ball valves play a crucial role in streamlining industrial processes by ensuring efficient flow control in various applications. With the ongoing advancements in valve technology, the market for industrial valves, including pneumatic ball valves, is expected to witness significant growth. According to recent industry reports, the global industrial valve market is projected to expand considerably, driven by increased demand for durable and efficient components in sectors like oil and gas, chemical processing, and power generation. Pneumatic ball valves, with their quick operation and reliability, contribute to optimized plant uptime and overall process efficiency.

One key advantage of pneumatic ball valves is their ability to reduce operational risks through precise control mechanisms. As highlighted in recent insights, application-specific valves that are tailored to specific needs can significantly enhance performance. For instance, industries utilizing stainless steel or carbon steel valves can benefit from improved durability and resistance to corrosion, thereby extending the lifespan of their equipment.

Tips for selecting pneumatic ball valves include assessing the specific requirements of your system, such as pressure ratings, temperature limits, and the type of media being handled. Additionally, consider investing in high-quality actuation mechanisms to ensure smooth operation and maintenance, thereby mitigating the risk of failures that could disrupt industrial processes.

Key Advantages of Pneumatic Ball Valves Over Traditional Valve Types

Pneumatic ball valves are increasingly preferred in modern industrial applications due to their distinct advantages over traditional valve types such as gate or globe valves. According to a report by MarketsandMarkets, the global pneumatic valve market is projected to reach $11.92 billion by 2025, driven largely by industries that prioritize efficiency and reliability. The design of pneumatic ball valves allows for quick operation, reducing the actuation time to mere seconds, which is critical for processes that require swift system responses.

Another key advantage is their durability and low maintenance requirements. Research published in the Journal of Pressure Vessel Technology indicates that pneumatic ball valves have a significantly longer service life compared to conventional options due to fewer moving parts. This results in reduced wear and tear, thus minimizing downtime and repair costs. Additionally, the inherent sealing capability of the ball within the valve ensures minimal leakage, with studies showing that pneumatic ball valves can achieve leakage rates as low as 0.01%, making them an ideal choice for applications where maintaining pressure and containment is essential.

Applications of Pneumatic Ball Valves in Various Industries

Pneumatic ball valves play a crucial role in various industrial sectors, offering reliability and efficiency in fluid control. In the oil and gas industry, for instance, the use of pneumatic ball valves has increased significantly, with a report by MarketsandMarkets estimating that the global market for these valves is expected to grow at a CAGR of 5.1% from 2021 to 2026. Their ability to rapidly open and close with minimal energy input makes them ideal for applications involving high pressure and corrosive fluids, ensuring safe and efficient operation in critical processes.

In the food and beverage sector, pneumatic ball valves are vital for maintaining hygiene and operational efficiency. A study published in the Journal of Food Engineering highlighted that the use of automated valves reduces the likelihood of contamination during processing. With food safety regulations becoming increasingly stringent, industries are turning to pneumatic ball valves as a solution to ensure compliance while optimizing workflow. Furthermore, in wastewater treatment facilities, these valves aid in achieving precise flow control, enhancing treatment efficacy in line with the Environmental Protection Agency's standards for water quality management.

Applications of Pneumatic Ball Valves in Various Industries

Factors Influencing the Selection of Pneumatic Ball Valves

When selecting pneumatic ball valves for industrial applications, several key factors should be taken into consideration. One of the primary considerations is the operating environment, which can include temperature, pressure, and the presence of corrosive substances. These variables affect not only the material selection but also the valve's ability to withstand the specific conditions of the application. For instance, high temperatures may necessitate the use of specialized materials that can maintain integrity without warping or degrading.

Another critical factor is the size and flow requirements of the system. The valve's diameter must match the piping specifications to ensure optimal flow rates and minimize pressure drops. Additionally, understanding the type of actuation needed, whether single-acting or double-acting, will also influence the ease of operation and response times. Compatibility with control systems and automation needs is essential for seamless integration into existing workflows. Ultimately, a thorough evaluation of these factors ensures that the selected pneumatic ball valve meets the operational demands, enhances efficiency, and provides reliable performance in modern industrial settings.

Maintenance and Reliability of Pneumatic Ball Valves in Industrial Settings

Pneumatic ball valves play a crucial role in maintaining efficient operations within industrial settings. These valves, known for their quick actuation and reliable performance, require regular maintenance to ensure their longevity and functionality. Routine inspections, lubrication of moving parts, and testing of both the actuator and valve positioning are essential tasks that can prevent unexpected failures. Implementing a preventive maintenance schedule not only minimizes downtime but also enhances the overall safety of the industrial process.

Pneumatic ball valves play a crucial role in maintaining efficient operations within industrial settings. These valves, known for their quick actuation and reliable performance, require regular maintenance to ensure their longevity and functionality. Routine inspections, lubrication of moving parts, and testing of both the actuator and valve positioning are essential tasks that can prevent unexpected failures. Implementing a preventive maintenance schedule not only minimizes downtime but also enhances the overall safety of the industrial process.

Reliability is paramount in any industrial application, and pneumatic ball valves are no exception. When properly maintained, these valves can withstand high pressures and extreme temperatures, making them suitable for a wide range of applications, such as chemical processing and water treatment. Additionally, adopting advanced monitoring technologies, such as sensors that track valve performance in real time, can further enhance their reliability. This proactive approach allows operators to address potential issues before they escalate, ensuring continuous and efficient operation.

Related Posts

-

Future Trends in Metering Valve Technology at 2025 China Import and Export Fair

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

How to Choose the Right Industrial Valves for Your Manufacturing Needs

-

Understanding the Benefits and Applications of Lockable Ball Valves in Industrial Settings

-

How to Choose the Right Ball Check Valve for Your Industrial Applications

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide