Understanding the Importance of Air Valve Types in Industrial Applications

In industrial applications, the significance of choosing the appropriate air valve type cannot be overstated. Air valves play a crucial role in regulating air flow, ensuring system efficiency, and maintaining operational safety. According to a recent industry report by MarketsandMarkets, the global air valves market is projected to reach USD 6.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.2% from 2020. This growth is driven by increasing automation in manufacturing processes and the rising demand for energy-efficient systems across various sectors. With diverse types of air valves available, including relief valves, control valves, and pressure-reducing valves, understanding their distinct functionalities and applications is essential for optimizing system performance and reliability.

This blog will delve into the various types of air valves, their specific uses, and the critical factors to consider when selecting them for industrial systems.

This blog will delve into the various types of air valves, their specific uses, and the critical factors to consider when selecting them for industrial systems.

Key Functions and Roles of Air Valves in Industrial Systems

Air valves play a crucial role in maintaining efficiency and safety in various industrial systems, from water treatment facilities to manufacturing plants. These valves control the flow of air within a system, performing essential functions such as preventing backflow, regulating pressure, and facilitating the release of accumulated air. According to a report by the International Society of Automation, improper air valve management can lead to operational inefficiencies costing industries up to 20% of their total energy expenses. This highlights the need for choosing the right type of air valve tailored to specific application requirements.

When selecting air valves, it's vital to consider the key functions they perform. For instance, automatic air valves are designed to detect and eliminate trapped air, which can lead to reduced system performance and potential equipment damage. Likewise, pressure relief valves are essential in preventing overpressurization in systems, which can cause hazardous situations and costly downtime. As per research published by the American Society of Mechanical Engineers, regular maintenance and strategic placement of air valves can improve overall system reliability by as much as 30%.

Tip: Regularly inspect and maintain air valves to ensure they are functioning correctly. This can help prevent air blockages and ensure optimal system performance. Additionally, conducting a thorough system analysis before installation can help identify the most effective air valve types for your needs.

Different Types of Air Valves and Their Unique Applications

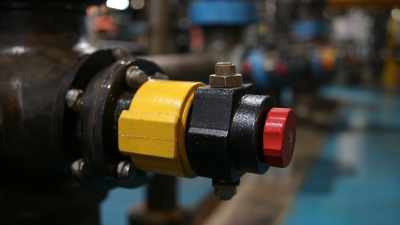

Air valves are essential components in various industrial applications, each designed to fulfill specific operational needs. The most common types include solenoid valves, pneumatic valves, and pressure relief valves.

Solenoid valves utilize electromagnetic mechanisms to control airflow, making them ideal for automated systems where precise control is necessary. These valves are often used in automation and robotics, ensuring that air is delivered or shut off effectively at a rapid pace.

Air valves are essential components in various industrial applications, each designed to fulfill specific operational needs. The most common types include solenoid valves, pneumatic valves, and pressure relief valves.

Solenoid valves utilize electromagnetic mechanisms to control airflow, making them ideal for automated systems where precise control is necessary. These valves are often used in automation and robotics, ensuring that air is delivered or shut off effectively at a rapid pace.

Pneumatic valves, on the other hand, are crucial in systems that rely on compressed air. They offer a versatile solution for controlling air pressure and flow in industries such as manufacturing and packaging. These valves can handle a wide range of applications from powering machinery to controlling conveyor systems, emphasizing their adaptability in complex settings. Additionally, pressure relief valves play a significant role in safeguarding equipment by preventing overpressure situations. They are commonly found in HVAC systems, helping to maintain safe operating conditions and prolonging the life of machinery. Each type of air valve brings unique advantages, tailored to meet the diverse demands of industrial environments.

Factors to Consider When Choosing Air Valve Types for Your Industry

When selecting air valve types for industrial applications, several critical factors must be considered to ensure optimal performance and efficiency. The global sanitary pumps and valves market is projected to reach USD 3.1 billion by 2033, growing at a CAGR of 3.7%, highlighting the increasing significance of valves in various industries. Key considerations include the specific requirements of the application, compatibility with existing systems, and the material properties of the valves, which can significantly affect durability and reliability in diverse environmental conditions.

Moreover, as industries increasingly embrace cleaner energy solutions, air valves are becoming integral to the liquefied natural gas (LNG) sector. The demand for pneumatic control in hydraulic systems also underscores the versatility of air valves, as they offer safe and cost-effective methods for system management. With the HVAC valve market expected to expand from USD 5.84 billion in 2024 to USD 8.06 billion by 2032, the selection of appropriate valve types becomes crucial for energy efficiency and compliance with regulatory standards, emphasizing the importance of thorough analysis when making these selections.

Understanding the Importance of Air Valve Types in Industrial Applications

This chart illustrates the distribution of different types of air valves used in various industrial applications. Understanding how each type performs and its prevalence can help in making informed decisions when selecting the right air valve for a specific purpose.

Maintenance Best Practices for Optimal Air Valve Performance

Air valves play a crucial role in the efficiency and reliability of industrial systems, primarily by regulating airflow and pressure. To ensure optimal air valve performance, regular maintenance is essential. According to the Fluid Control Institute, improper maintenance can lead to a decrease in valve lifespan by up to 30%, potentially resulting in costly downtimes and repairs. A systematic approach to maintenance not only prolongs the life of these valves but also enhances the overall productivity of the industrial process.

To maintain air valves effectively, it's vital to implement a routine inspection schedule. This includes checking for common issues such as leaks, corrosion, or blockage. The Institute of Electrical and Electronics Engineers reports that maintaining valves in peak condition can yield energy savings of around 15-20%. Additionally, clean filters and seals can prevent unnecessary wear, thus ensuring better flow rates and reduced energy consumption.

Tips for Optimal Maintenance:

- Regularly inspect and clean air filters to prevent clogging.

- Lubricate moving parts according to the manufacturer’s specifications to reduce friction.

- Consider using online monitoring systems to track valve performance and detect issues early.

By adhering to these best practices, industries can significantly improve air valve reliability and functionality.

Innovations and Future Trends in Air Valve Technology for Industry

In recent years, advancements in air valve technology have transformed the landscape of industrial applications, enhancing efficiency and reliability. Innovations such as smart air valves equipped with IoT capabilities are revolutionizing the way industries manage airflow. These valves can monitor pressure and flow rates in real-time, providing crucial data that allows for quicker response times and improved operational efficiency. As industries increasingly focus on automation, the integration of sensor technologies in air valves is set to become a standard practice, reducing manual oversight and minimizing the risk of errors.

Future trends indicate a shift toward sustainable and energy-efficient designs in air valve technology. Manufacturers are exploring the use of advanced materials that not only improve durability but also reduce environmental impact. The adoption of energy-saving features, such as variable flow control systems, is becoming prevalent, enabling industries to operate more sustainably while cutting costs. Additionally, as regulatory standards become more stringent, the development of air valves that comply with these guidelines will be essential, pushing innovation to the forefront of industrial air management solutions.

Related Posts

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

Understanding the Functionality of Ball Check Valves in Fluid Control Systems

-

Unmatched Excellence in PTFE Lined Check Valves: Crafted in China, Delivered Worldwide

-

How to Choose the Right Ball Check Valve for Your Industrial Applications

-

Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One