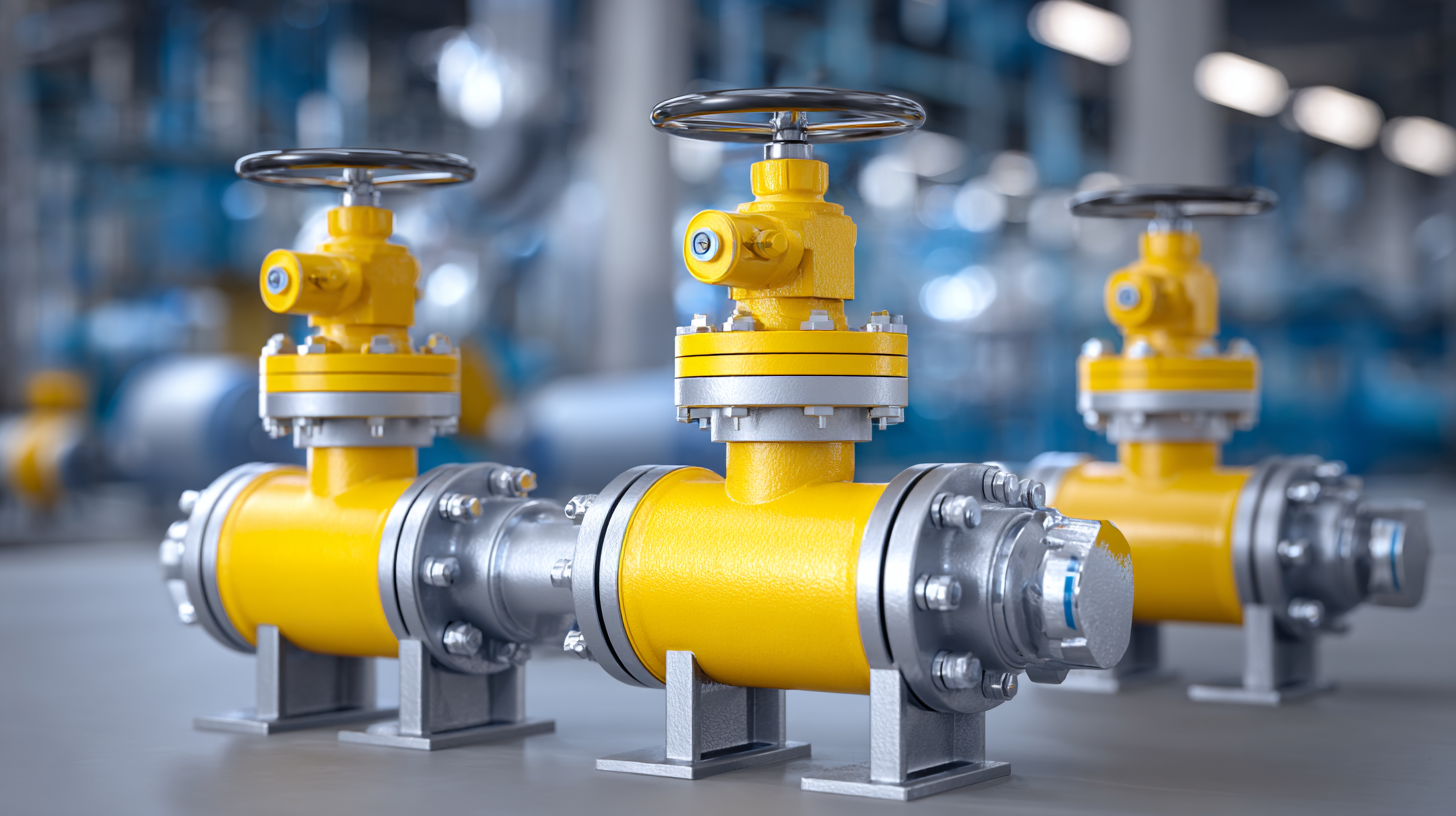

How to Choose the Right Industrial Valves for Your Manufacturing Needs

Choosing the right industrial valves is crucial for optimizing your manufacturing processes and ensuring operational efficiency. With a wide range of valve types available, including gate, globe, ball, and butterfly valves, each designed for specific applications and conditions, the selection process can be daunting. Understanding the unique requirements of your manufacturing needs, such as pressure ratings, temperature tolerances, and compatibility with different fluids, is essential to making an informed decision.

Choosing the right industrial valves is crucial for optimizing your manufacturing processes and ensuring operational efficiency. With a wide range of valve types available, including gate, globe, ball, and butterfly valves, each designed for specific applications and conditions, the selection process can be daunting. Understanding the unique requirements of your manufacturing needs, such as pressure ratings, temperature tolerances, and compatibility with different fluids, is essential to making an informed decision.

Additionally, considerations like materials, size, and regulatory compliance can significantly impact the performance and longevity of industrial valves within your system. This guide will walk you through essential factors to consider, helping you make the best choices that align with your operational goals and contribute to the overall success of your manufacturing endeavors.

Identifying Your Specific Manufacturing Requirements for Valves

When selecting industrial valves for your manufacturing processes, it's crucial to first identify your specific requirements. Consider factors such as the type of fluid being controlled, temperature ranges, and pressure levels. Each application may demand different materials and valve types – for instance, corrosive fluids may require plastic or specialized metal valves for durability.

Tip: Always assess the compatibility of the valve material with the media it will handle. This ensures safe operation and longevity of the valve.

Additionally, evaluate the actuator type that suits your operational needs. Choices range from manual to automated systems, affecting responsiveness and control precision. Analyzing the workflow and the environment helps determine whether electric, pneumatic, or hydraulic actuators are the best fit.

Tip: Conduct a thorough analysis of your workflow to determine if automation could enhance efficiency, as this may have implications for your valve selection.

By carefully considering these factors, you can streamline the decision-making process for industrial valves and improve the overall efficiency and safety of your manufacturing operations.

Understanding Different Types of Industrial Valves and Their Applications

Industrial valves play a crucial role in various manufacturing processes, controlling the flow of fluids and gases through piping systems. Understanding the different types of industrial valves and their specific applications is essential for making the right choice for your operational needs. Common types include gate valves, globe valves, ball valves, and butterfly valves, each serving unique functions. For instance, gate valves are best suited for on/off control, while globe valves are ideal for throttling purposes. Ball valves offer quick shut-off capabilities, and butterfly valves are preferred for large volumes due to their space-saving design.

Industrial valves play a crucial role in various manufacturing processes, controlling the flow of fluids and gases through piping systems. Understanding the different types of industrial valves and their specific applications is essential for making the right choice for your operational needs. Common types include gate valves, globe valves, ball valves, and butterfly valves, each serving unique functions. For instance, gate valves are best suited for on/off control, while globe valves are ideal for throttling purposes. Ball valves offer quick shut-off capabilities, and butterfly valves are preferred for large volumes due to their space-saving design.

Tips: When selecting industrial valves, consider factors such as pressure rating, temperature tolerance, and the type of media being controlled. It’s also important to evaluate the valve material to ensure compatibility with the fluid or gas. Additionally, assess the function—whether it’s for throttling or on/off control—to determine the most effective valve type for your specific application. Engaging with suppliers or valve manufacturers can provide deeper insights into the specifications you may need.

By paying attention to these details, you can better navigate the complexities of valve selection, ensuring optimal performance and longevity of your manufacturing operations. Properly chosen valves not only enhance efficiency but also contribute to the overall safety and effectiveness of your systems.

Evaluating Valve Materials and Compatibility with Process Fluids

When selecting industrial valves for manufacturing processes, evaluating the materials and their compatibility with process fluids is crucial. Different valve materials, such as stainless steel, brass, and plastics, possess unique properties that can impact their performance and longevity.

For example, stainless steel valves are excellent for high-pressure applications and corrosive fluids due to their strength and resistance to oxidation. In contrast, plastic valves might be preferred for less aggressive fluids, offering lightweight and cost-effective solutions.

Moreover, understanding the chemical compatibility of the chosen material with the specific process fluid is essential. Certain materials can degrade or react adversely when exposed to specific chemicals, leading to valve failure and potential safety hazards. Conducting a thorough analysis of process fluid characteristics, including temperature, pressure, and chemical composition, will help in selecting the right valve materials. This ensures operational efficiency and enhances the reliability of the manufacturing process while minimizing maintenance costs and downtime.

Considering Pressure Ratings and Temperature Resistance for Valve Selection

When selecting industrial valves for manufacturing needs, understanding pressure ratings and temperature resistance is crucial. Pressure ratings indicate the maximum pressure a valve can handle safely. It's essential to match the valve's pressure rating with your system's operating conditions to prevent leaks or failures that could disrupt production or lead to safety hazards. Always consult manufacturer specifications and consider the worst-case scenarios your system may encounter.

Temperature resistance is equally important, as different valves are designed to operate within specific temperature ranges. A valve that cannot withstand high temperatures may become deformed or fail, potentially damaging your equipment or halting operations. Assessing the temperature profiles of your processes can help you choose valves that will maintain their performance over time.

**Tips:**

- Check the pressure ratings on the data sheet for each valve model, ensuring they exceed your system's maximum operating pressure.

- Monitor typical and peak temperatures in your application to choose a valve that accommodates both, taking into consideration any seasonal changes that may affect temperature.

Pressure Ratings and Temperature Resistance of Industrial Valves

Assessing Maintenance and Lifecycle Costs When Choosing Industrial Valves

When selecting industrial valves for manufacturing applications, assessing maintenance and lifecycle costs is crucial for long-term efficiency and profitability. According to a recent report by the National Association of Manufacturers, maintenance costs can account for up to 30% of a facility's operating budget. This underscores the importance of choosing valves that not only meet operational requirements but also minimize ongoing maintenance expenses. For instance, investing in high-quality, durable valves can significantly reduce the frequency and cost of replacements, leading to lower overall lifecycle costs.

Additionally, a study by the Industrial Valve Association revealed that valves with advanced materials and technologies, such as corrosion resistance and self-sealing capabilities, can extend service life by over 50%. This translates to fewer interruptions in production and less downtime, which is crucial in a fast-paced manufacturing environment. Understanding these cost factors empowers manufacturing leaders to make informed decisions that align with their operational goals while securing a sustainable bottom line. By prioritizing valves that offer long-term reliability and reduced maintenance needs, companies can enhance their overall manufacturing efficiency.

Related Posts

-

Ultimate Guide to Selecting the Right Industrial Valves for Your Applications

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One

-

Understanding the Benefits and Applications of Lockable Ball Valves in Industrial Settings

-

How to Optimize Your Pipeline Efficiency with Ball Check Valves: Best Practices and Insights