How to Choose the Right Ball Check Valve for Your Industrial Applications

In the world of industrial applications, selecting the right components can significantly impact efficiency and safety. Among these critical components, the ball check valve plays a vital role in preventing backflow and ensuring the smooth operation of various systems. Understanding the characteristics and functionalities of different types of ball check valves is essential for engineers and decision-makers alike. This blog will delve into the various types of ball check valves available in the market, discussing their design, materials, and applications. By the end, you will gain valuable insights into how to choose the right ball check valve for your specific needs, ultimately contributing to enhanced performance and reliability in your industrial processes.

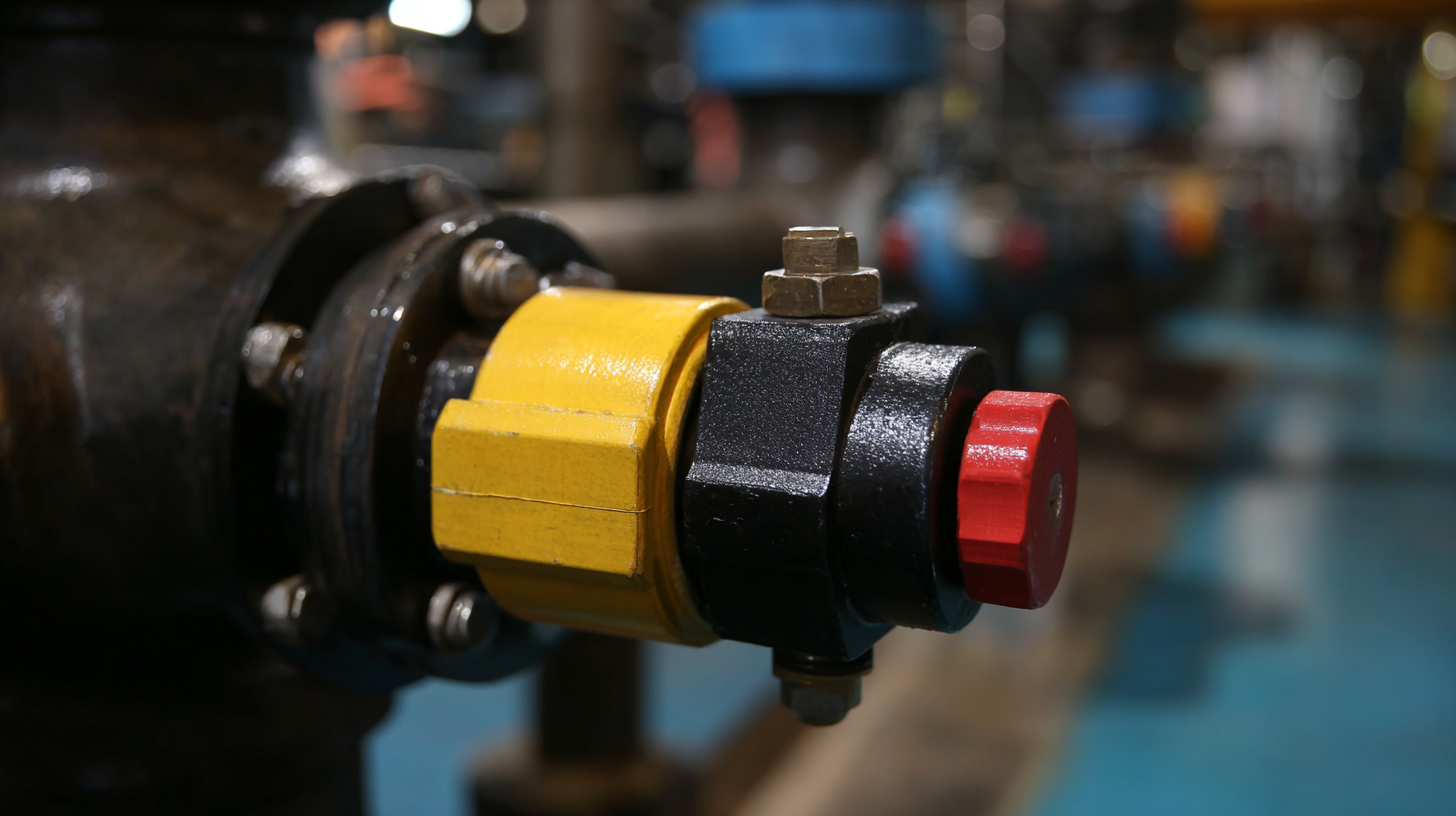

Understanding Ball Check Valve Basics and Applications

When selecting a ball check valve for industrial applications, it’s crucial to understand the fundamentals of how they operate and their specific applications. Ball check valves are designed to allow fluid to flow in one direction while preventing backflow, which makes them invaluable in various systems. Typically employed in sewage systems, water treatment plants, and chemical processing, these valves maintain system integrity and efficiency.

Tips: When assessing the suitability of a ball check valve, consider factors such as pressure, temperature, and the type of fluid being transported. Ensure that the valve material is compatible with the fluid to avoid corrosion or damage. Additionally, assess the required flow capacity; selecting a valve that meets or exceeds these specifications is critical for optimal performance.

Another key consideration is the valve size and installation orientation. Small changes in settings can lead to variations in flow dynamics. Proper installation can prevent turbulence and ensure smooth operation. Always refer to manufacturer guidelines for positioning and maintenance to enhance valve lifespan and reliability in your industrial setup.

Key Factors to Consider When Selecting a Ball Check Valve

When selecting the right ball check valve for your industrial applications, several key factors must be considered to ensure optimal performance and reliability. According to a report by the American Society of Mechanical Engineers (ASME), improper selection can lead to inefficiencies and increased operational costs. One significant criterion is the valve material, as it directly influences the valve's durability and compatibility with the fluids being transported.

Materials such as stainless steel are preferred for corrosive environments, while PVC may be suitable for less abrasive applications.

Another critical element is the valve size. A study from the Hydraulic Institute indicates that improperly sized valves can result in turbulence and pressure drops, leading to system inefficiencies. Ensuring that the ball check valve matches the flow rate and pressure specifications of your system is vital.

Additionally, factors such as the installation environment and maintenance accessibility should not be overlooked, as these can affect the long-term functionality and safety of the valve.

By carefully evaluating these factors, industries can improve operational efficiency and minimize downtime.

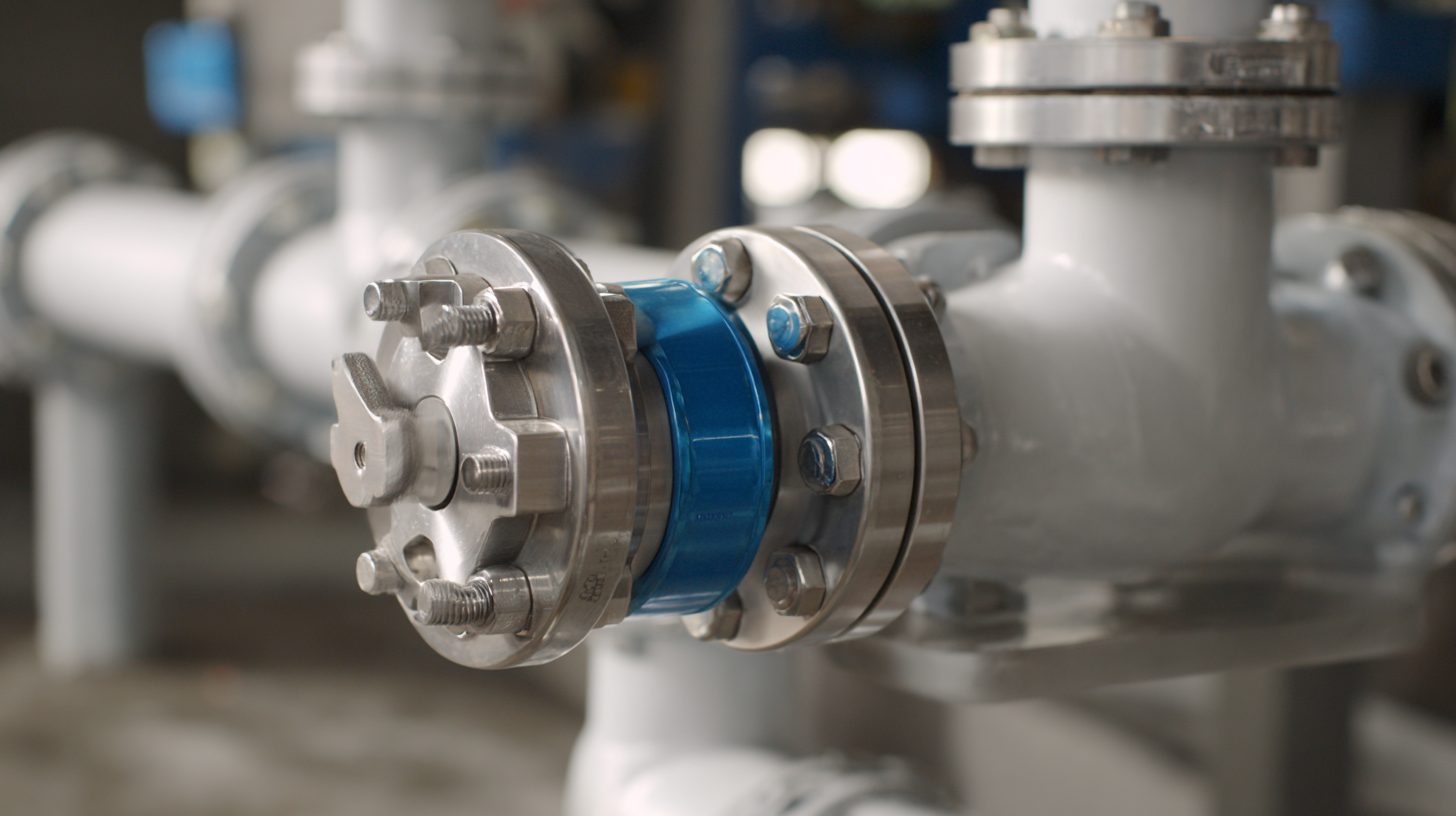

Material Selection: Choosing the Right Construction for Your Needs

When selecting a ball check valve for industrial applications, material selection is crucial to ensuring long-term performance and reliability. The construction of the valve directly impacts its resistance to corrosion, pressure, temperature, and the specific chemicals it will encounter. Therefore, understanding the environment in which the valve will operate is the first step in material selection. For instance, if the valve will handle corrosive substances, materials such as stainless steel or specialized plastics might be the best choice to prevent degradation.

When selecting a ball check valve for industrial applications, material selection is crucial to ensuring long-term performance and reliability. The construction of the valve directly impacts its resistance to corrosion, pressure, temperature, and the specific chemicals it will encounter. Therefore, understanding the environment in which the valve will operate is the first step in material selection. For instance, if the valve will handle corrosive substances, materials such as stainless steel or specialized plastics might be the best choice to prevent degradation.

Additionally, the operating conditions, such as temperature and pressure, should guide the selection process. High-temperature applications may require valves made from materials like brass or certain alloys that can withstand extreme conditions without compromising integrity. In contrast, low-pressure environments might allow for the use of lighter, less expensive materials. Ultimately, choosing the right construction based on these factors will not only enhance the valve's functionality but also optimize the overall efficiency of industrial systems. Careful consideration of these aspects results in a ball check valve that meets your specific needs while ensuring durability and safety.

Sizing and Flow Rate Analysis for Optimal Performance

When selecting a ball check valve for industrial applications, sizing and flow rate analysis are critical to ensure optimal performance. According to a recent industry report from the Flow Control Association, improper valve sizing can lead to significant inefficiencies, with flow restrictions causing pressure drops of 10% to 25%. Therefore, accurately assessing your system's flow rate is paramount. For example, if your operation typically experiences a flow rate of 100 GPM (gallons per minute), you would need a valve capable of sustaining such throughput without causing turbulence or excess backpressure.

Additionally, the American Society of Mechanical Engineers (ASME) emphasizes the importance of considering both the maximum and minimum flow rates during valve selection. This is particularly relevant in fluctuating operational environments where flow rates may vary significantly. Choosing a ball check valve with a suitable Cv (flow coefficient) can help you maintain consistent flow, minimizing the risk of cavitation or hydraulic shock. Reports indicate that an appropriately sized valve can enhance system efficiency by up to 30%, ultimately leading to reduced operational costs and improved longevity of the equipment.

By thoroughly analyzing your system's specific needs and utilizing industry data on flow rates and valve sizing, you can ensure that the ball check valve selected will function seamlessly within your operational parameters, promoting reliable performance across your industrial applications.

Maintenance Tips for Longevity of Ball Check Valves in Industry

When it comes to maintaining ball check valves in industrial applications, regular upkeep is vital for ensuring long-term functionality and efficiency. A study by the Fluid Control Institute indicates that approximately 30% of valve failures are attributed to inadequate maintenance practices. To mitigate this risk, operators should establish a routine inspection schedule that focuses on identifying wear and tear, particularly in the sealing elements and ball movement mechanisms. Regular checks can help in early detection of leaks or blockages, which can prevent costly downtime and extend the service life of the valves.

Additionally, it’s essential to consider the environmental conditions in which the valves operate. The American Society of Mechanical Engineers (ASME) notes that valves exposed to corrosive substances can suffer significantly without proper protection. Employing protective coatings or selecting materials compatible with the media being controlled can enhance the durability of the valves. Operators should also ensure that the valves are installed at optimal angles and with proper alignment to facilitate smooth operation and reduce the risk of mechanical failure over time. By adhering to best practices in maintenance and material selection, industries can achieve greater reliability and efficiency from their ball check valves.

Importance of Various Factors in Choosing Ball Check Valves

This bar chart illustrates the rated importance of various factors to consider when selecting a ball check valve for industrial applications. The factors include Material Durability, Temperature Resistance, Pressure Handling, Size Options, and Maintenance Frequency, rated on a scale from 1 to 10.

Related Posts

-

Understanding the Functionality of Ball Check Valves in Fluid Control Systems

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

Mastering Ball Valve Selection: A Comprehensive Tutorial for Optimal Flow Control in Industrial Applications

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

Mastering BFV Valves: A Comprehensive Tutorial on Selection, Sizing, and Optimization Techniques