Understanding the Benefits of Ball Check Valves in Industrial Applications: A Comprehensive Guide

In the realm of industrial applications, the significance of efficient fluid control mechanisms cannot be overstated. Among these, the ball check valve stands out as a critical component, contributing to operational reliability and safety. According to a recent market analysis by Allied Market Research, the global ball check valve market is expected to reach USD 4.5 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.2% from 2020 to 2027. This growth is driven by the increasing demand for fluid handling systems in various sectors such as oil and gas, water treatment, and chemical manufacturing. Ball check valves play a pivotal role by preventing backflow, thereby safeguarding equipment and enhancing overall system efficiency. As industries continue to innovate, understanding the comprehensive benefits of ball check valves becomes essential for optimizing processes and maintaining high standards of operational integrity.

Overview of Ball Check Valves and Their Functionality

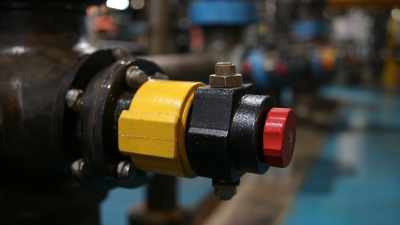

Ball check valves are essential components in various industrial applications, providing reliable one-way flow control to prevent backflow, thereby safeguarding equipment and processes. The design of these valves features a spherical ball that moves within a seat, allowing fluid to pass in one direction while sealing off reverse flow effectively. According to a report by Mordor Intelligence, the global ball valve market is projected to reach USD 10.46 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth underscores the increasing reliance on such valves in sectors like oil and gas, water and wastewater, and chemical processing.

The functionality of ball check valves is primarily defined by their ability to respond to the pressure differential between the intake and discharge sides. When the flow direction aligns with the valve's opening, the ball is pushed away from the seat, facilitating fluid passage. Conversely, if backflow occurs, the ball moves back into the seat, effectively blocking the flow. This mechanism is crucial for maintaining system integrity and efficiency. According to a study by ResearchAndMarkets, the need for preventing contamination and ensuring safety standards in industrial fluid systems has driven the demand for high-quality ball check valves, highlighting their significance in operational performance across various industries.

Key Advantages of Using Ball Check Valves in Industrial Systems

Ball check valves play a crucial role in optimizing the efficiency of industrial systems. One of the key advantages of these valves is their ability to prevent backflow, ensuring that fluids move in a single direction. This feature is essential for maintaining system integrity and preventing contamination, especially in applications involving chemicals or sensitive materials. The design of ball check valves allows them to respond to pressure changes effectively, closing off automatically when backflow attempts occur, thus safeguarding the entire system.

Another significant benefit of ball check valves is their durability and low maintenance requirements. Crafted from robust materials, these valves can withstand harsh conditions and are resistant to wear and tear over time. Their simple yet effective mechanism ensures reliable operation, reducing the need for frequent inspections and repairs. This reliability is particularly advantageous in industrial settings where downtime can lead to substantial financial losses. Consequently, incorporating ball check valves into industrial applications can enhance operational efficiency and reduce long-term costs.

Benefits of Ball Check Valves in Industrial Applications

Applications and Industries Benefiting from Ball Check Valves

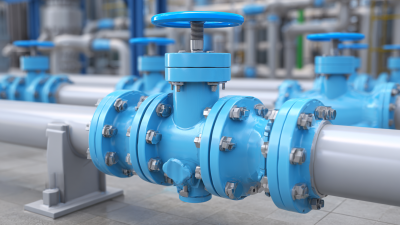

Ball check valves are crucial components across various industrial sectors, playing a vital role in ensuring fluid regulation and preventing backflow. Industries such as oil and gas, water treatment, and chemical processing utilize these valves to enhance operational efficiency. According to a report by Markets and Markets, the global ball valve market is projected to grow from USD 10.2 billion in 2020 to USD 12.8 billion by 2025, indicating a compound annual growth rate (CAGR) of 4.4%. This growth is largely driven by the high demand for reliable and durable fluid control solutions.

In the water treatment industry, ball check valves help maintain consistent pressure levels and prevent contamination in potable water systems. The American Water Works Association (AWWA) underscores that effective backflow prevention can significantly reduce the risk of waterborne diseases, highlighting the importance of these valves in safeguarding public health. Similarly, the chemical processing sector benefits from their resistance to corrosive substances, allowing for safer handling of aggressive fluids. These applications demonstrate the integral role ball check valves play in enhancing both efficiency and safety across multiple industrial domains.

Understanding the Benefits of Ball Check Valves in Industrial Applications

| Application | Industry | Key Benefits | Common Materials |

|---|---|---|---|

| Wastewater Management | Environmental Services | Prevents backflow, enhances safety | PVC, Stainless Steel |

| Hydraulic Systems | Manufacturing | Increases efficiency, reduces leaks | Brass, Aluminum |

| Oil and Gas Processing | Energy | Durable under extreme conditions | Carbon Steel, Alloy Steel |

| Food and Beverage Production | Food Industry | Ensures hygiene, prevents contamination | Stainless Steel, Plastic |

| Cooling Systems | HVAC | Enhances system reliability | Copper, Synthetic Materials |

Installation and Maintenance Best Practices for Ball Check Valves

When installing ball check valves, proper placement and alignment are crucial for ensuring optimal performance. First, it is essential to install the valves in the correct orientation, typically with the flow direction indicated by an arrow on the valve body. This orientation allows the valve to effectively prevent backflow. Additionally, ensuring that the valve is mounted securely and that the surrounding piping aligns well with the valve's inlet and outlet will help prevent any stress that may lead to leaks or valve failure.

Maintenance of ball check valves involves periodic inspection and cleaning to prevent the accumulation of debris, which can hinder valve operation. Regular checks should be made for signs of wear or damage, particularly to the seat and ball. Depending on the application, lubrication may also be necessary, but care should be taken to use compatible lubricants to avoid damaging the valve materials. By adhering to these best practices, industrial facilities can enhance the longevity and reliability of ball check valves, leading to improved operational efficiency.

Comparative Analysis: Ball Check Valves vs. Other Check Valve Types

When comparing ball check valves to other types of check valves, such as swing and lift check valves, several key differences emerge that can influence their effectiveness in industrial applications. Ball check valves feature a simple design with a spherical ball that seals against a seat, preventing backflow. This mechanism provides a more reliable sealing capability, especially in high-pressure systems. In contrast, swing check valves depend on a hinged disc that swings open and closed, which may not seal as effectively under varying flow conditions.

Another advantage of ball check valves lies in their ability to handle a wide range of fluid types, including viscous liquids and slurries. Their smooth internal surfaces discourage the accumulation of debris and sediment, reducing maintenance needs and improving longevity. On the other hand, lift check valves operate with a movable disc that can be more susceptible to wear and tear, especially in applications where there are rapid changes in fluid velocity. Thus, while all check valves serve a fundamental purpose, ball check valves often provide superior performance and reliability for demanding industrial environments.

Related Posts

-

How to Choose the Right Ball Check Valve for Your Industrial Applications

-

Understanding the Role of Check Valves in Fluid Control Systems for Enhanced Efficiency

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide

-

What is a Check Valve and How Does It Work in Fluid Systems

-

Unmatched Excellence in PTFE Lined Check Valves: Crafted in China, Delivered Worldwide

-

Ultimate Guide to Selecting the Right Industrial Valves for Your Applications