Understanding the Benefits and Applications of Lockable Ball Valves in Industrial Settings

In the industrial sector, the importance of safety and efficiency in fluid control systems cannot be overstated. Among various valve types, the lockable ball valve stands out due to its superior features that enhance operational reliability and security. According to a recent report by ResearchAndMarkets, the global industrial valve market is projected to reach $91.4 billion by 2026, with the demand for lockable ball valves significantly contributing to this growth due to their ability to prevent unauthorized access and accidental fluid discharge. These valves not only provide a durable and leak-proof performance but also comply with stringent safety standards. As industries strive to optimize their processes while mitigating risks, understanding the benefits and applications of lockable ball valves becomes imperative for achieving both operational excellence and safety compliance. This blog will explore these advantages and guide you through the optimal usage of lockable ball valves in various industrial settings.

Advantages of Lockable Ball Valves in Operational Safety and Efficiency

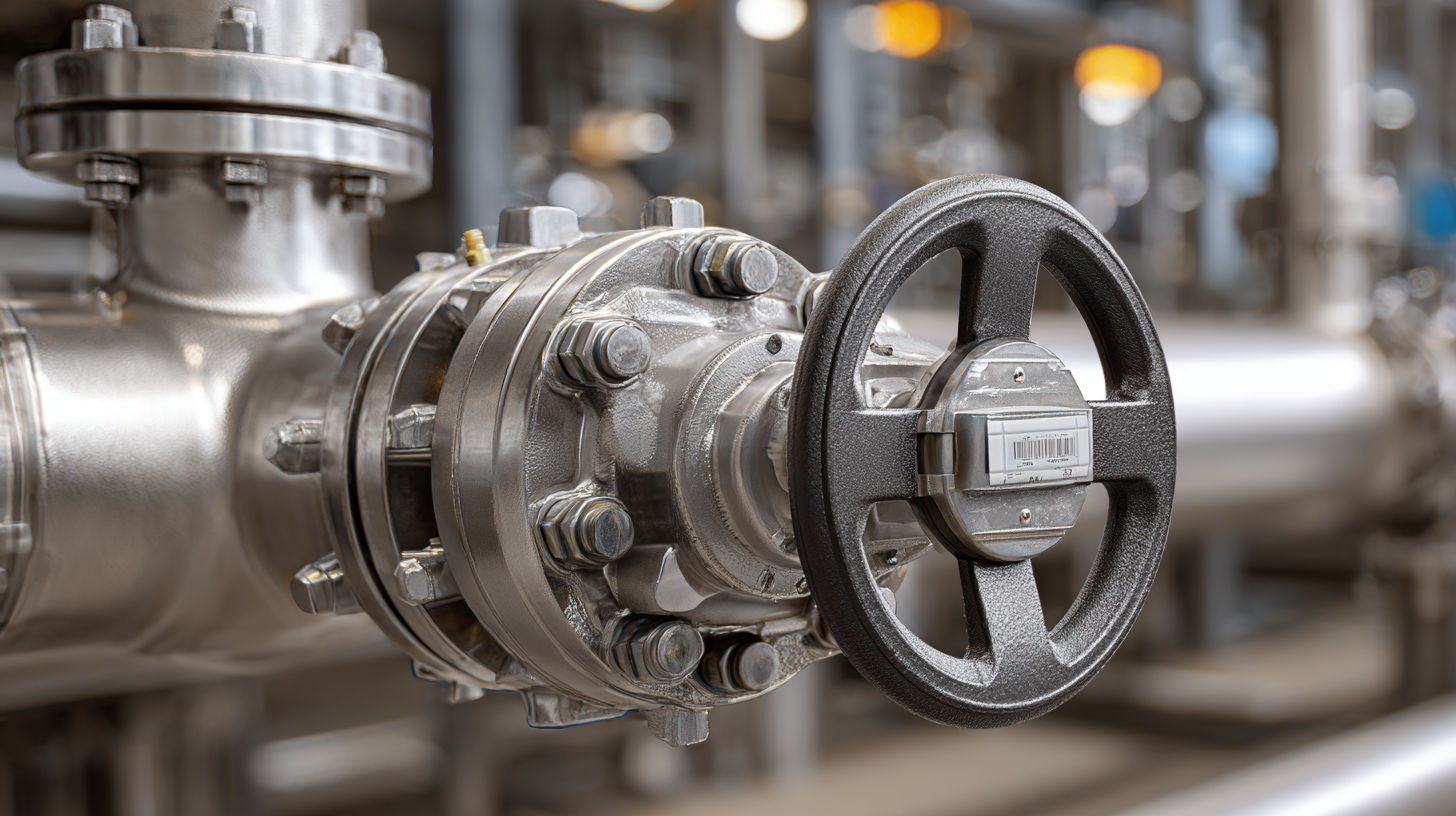

Lockable ball valves have become essential components in various industrial applications, primarily due to their significant contributions to operational safety. One of the foremost advantages of these valves is their ability to prevent accidental leaks or unintended operation. The locking mechanism ensures that the valve remains in a designated position, whether fully open or closed, thereby safeguarding against unexpected fluid release. This feature is especially critical in environments dealing with hazardous materials, where even a minor leak can lead to costly damage or safety hazards for personnel.

In addition to enhancing safety, lockable ball valves also play a vital role in improving operational efficiency. By providing a reliable means of controlling fluid flow, they enable precise management of processes across different systems. When paired with smart monitoring technologies, these valves allow for real-time tracking of fluid dynamics, facilitating proactive maintenance and reducing downtime. As a result, industries can maximize productivity while minimizing risks associated with malfunctioning equipment. The integration of lockable ball valves thus not only bolsters safety protocols but also streamlines operational workflows.

Key Industries Benefiting from Lockable Ball Valve Applications

Lockable ball valves are increasingly recognized for their essential role in various industrial settings, providing not only superior flow control but also added security features. One of the key industries benefiting from these valves is the oil and gas sector, where the need for reliable sealing mechanisms is critical. Lockable ball valves ensure that the flow of hazardous materials can be securely managed, preventing accidental releases and enhancing safety protocols. Their robust construction and ease of operation make them ideal for handling high-pressure applications in this sector.

Lockable ball valves are increasingly recognized for their essential role in various industrial settings, providing not only superior flow control but also added security features. One of the key industries benefiting from these valves is the oil and gas sector, where the need for reliable sealing mechanisms is critical. Lockable ball valves ensure that the flow of hazardous materials can be securely managed, preventing accidental releases and enhancing safety protocols. Their robust construction and ease of operation make them ideal for handling high-pressure applications in this sector.

Another industry that capitalizes on the advantages of lockable ball valves is the water treatment sector. These valves help regulate water flow and maintain system integrity, crucial for both municipal and industrial uses. By incorporating lockable features, facilities can prevent unauthorized access and unintended valve operation, thereby safeguarding the treatment processes. Additionally, in the chemical manufacturing sector, these valves support stringent safety measures. They allow for the isolation of various chemicals, mitigating risks associated with leaks or spills while maintaining operational efficiency. Overall, the versatility of lockable ball valves makes them indispensable across multiple industries, contributing significantly to operational safety and reliability.

Installation and Maintenance Best Practices for Lockable Ball Valves

Lockable ball valves are essential components in industrial settings, ensuring both safety and efficiency in fluid control. Their design allows for secure shutting off of flow, providing a vital mechanism that prevents accidental discharge or unauthorized access to hazardous materials. According to a recent industry report, approximately 35% of industrial incidents arise from improper valve operation, which underscores the importance of installing reliable shut-off devices like lockable ball valves. These valves not only enhance safety but also comply with various standards that mandate robust fluid management systems.

When it comes to installation and maintenance of lockable ball valves, best practices are crucial to ensure their longevity and performance. It is recommended to conduct regular inspections and functionality tests to prevent leaks and operational failures. Additionally, following manufacturer guidelines for torque specifications during installation can mitigate risks associated with valve failure. A study by the Fluid Control Association indicates that proper maintenance can extend the life of valves by up to 25%, significantly reducing replacement costs and downtime in industrial operations. Implementing these practices not only safeguards personnel but also optimizes operational efficiency.

Comparative Analysis: Lockable Ball Valves vs. Other Valve Types

Lockable ball valves have emerged as a preferred choice in industrial settings due to their unique operational features and reliability. Unlike traditional gate or globe valves, which can be prone to leaks and require more manual effort to operate, lockable ball valves offer a straightforward design that enhances safety and efficiency. They are particularly advantageous in applications where the control of fluid flow is critical, as they provide a tight seal that minimizes the risk of leakage. The locking mechanism not only secures the valve in a specific position but also helps prevent unauthorized access, ensuring a safer working environment.

When comparing lockable ball valves to other types such as butterfly or gate valves, the differences become more apparent in terms of functionality and usage scenarios. Butterfly valves, while effective for on/off control, generally do not provide the same level of sealing as ball valves, making them less ideal for high-pressure systems. Gate valves, although excellent for minimal flow resistance, can suffer from operational complications in certain conditions. The versatility of lockable ball valves makes them suitable for a range of applications, from gas and water distribution to chemical processing, where reliability and safety are paramount. Their construction allows quick operation while maintaining a strong safeguard against accidental openings, setting them apart in the competitive landscape of industrial valves.

Understanding the Benefits and Applications of Lockable Ball Valves in Industrial Settings

This chart compares lockable ball valves against other valve types based on various performance metrics, showing the advantages of lockable ball valves in terms of flow control efficiency, leak prevention, maintenance requirements, cost efficiency, and durability.

Future Trends in Lockable Ball Valve Technology and Innovation

The future trends in lockable ball valve technology are steering the industry towards increased automation and enhanced safety features. A recent report from MarketsandMarkets predicts that the global market for ball valves is expected to reach USD 10.61 billion by 2025, growing at a CAGR of 5.3% from 2020. This growth is propelled by the rising demand for energy-efficient solutions and stringent safety regulations, particularly in industries like oil and gas, chemicals, and water treatment. Lockable ball valves play a pivotal role in ensuring operational integrity and preventing unauthorized access, thus aligning with these evolving industry standards.

Innovation in materials and designs is another key trend shaping the future of lockable ball valves. Advanced materials such as corrosion-resistant alloys and high-performance plastics are being developed, which enhances the durability and longevity of these valves in harsh industrial environments. According to a report by Allied Market Research, the adoption of smart valve technologies, including IoT connectivity, is expected to significantly increase, providing real-time monitoring capabilities. This integration of smart technologies not only improves operational efficiency but also enhances predictive maintenance capabilities, reducing downtime and extending the lifecycle of locking mechanisms, thereby setting a new standard for safety in industrial applications.