How to Choose the Right Steam Control Valve for Your Application

Choosing the right steam control valve for your application is a critical decision that can significantly impact system performance, efficiency, and safety. Steam control valves are essential components in various industrial processes, regulating steam flow and maintaining the desired pressure and temperature levels. The right selection ensures optimum operation while minimizing maintenance costs and energy consumption.

When evaluating the appropriate steam control valve, it is important to consider various factors such as the specific requirements of your application, including pressure ratings, flow characteristics, and the nature of the steam system. Understanding these parameters helps to identify the most suitable valve type and design, ensuring that it meets the demands of your operational environment. Additionally, proper knowledge of materials and sealing options can prevent common issues like leakage and corrosion, further enhancing the valve’s reliability.

In this guide, we will explore the key considerations and best practices for selecting steam control valves, equipping you with the knowledge necessary to make informed decisions. By doing so, you can optimize your steam system's efficiency and longevity, ultimately contributing to the overall success of your operations.

Read more »

By:Clara - December 24, 2025

By:Clara - December 24, 2025

Top 10 Tips for Choosing the Right PTFE Valve for Your Applications

Choosing the right PTFE valve for your specific applications can significantly impact operational efficiency and safety in varied industries, including pharmaceuticals, chemicals, and food processing. According to a report by the International Valve Association, the global valve market is projected to reach approximately $80 billion by 2025, with PTFE valves playing a crucial role in this growth due to their exceptional resistance to chemicals and high-temperature applications. This underscores the necessity for industries to carefully consider the selection of PTFE valves as they seek to enhance process reliability and performance.

As noted by industry expert Dr. Richard Melton, "Selecting the appropriate PTFE valve is not just about compatibility with the medium; it’s about understanding the entire system’s requirements to ensure optimal functionality and longevity." Dr. Melton's insights reflect a growing recognition within the sector that the success of industrial operations often hinges on the nuances of valve selection. In this article, we will explore the top ten tips for selecting the right PTFE valve, enabling professionals to make informed decisions that align with their operational needs and industry standards.

Read more »

By:Clara - December 19, 2025

By:Clara - December 19, 2025

How to Choose the Right Lined Valves for Your Industrial Applications

In the complex landscape of industrial applications, selecting the appropriate lined valves can significantly influence operational efficiency and system longevity. According to Dr. Emily Foster, a leading expert in valve technology, "The right lined valve is not merely a component; it is a cornerstone that ensures the integrity and reliability of the entire process system." As industries continue to evolve, the demand for high-performance lined valves has grown, necessitating a deeper understanding of their unique characteristics and applications.

Lined valves are critical in applications where corrosion resistance and fluid containment are paramount. The materials used in their lining can drastically affect their performance, making it essential for engineers and procurement specialists to grasp the various options available. This profound selection process is not just about meeting standard specifications; it involves careful consideration of the specific conditions under which the valves will operate. By doing so, industries can safeguard against failures that disrupt operations and compromise safety.

Choosing the right lined valves is a strategic decision that transcends simple functionality. It intertwines with broader considerations such as cost-effectiveness, longevity, and compliance with industry standards. With expert insights and a structured approach, organizations can navigate the complexities involved in this selection, ensuring that they invest in solutions that offer optimal performance and reliability in their unique industrial contexts.

Read more »

By:Clara - December 15, 2025

By:Clara - December 15, 2025

What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems

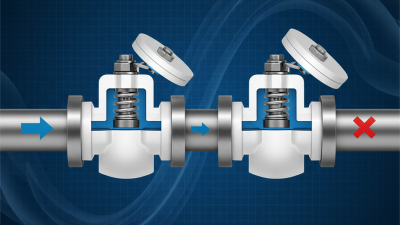

In fluid systems, maintaining unidirectional flow is essential for optimal performance and safety. One key component in achieving this is the PTFE lined check valve. This innovative valve design integrates a Teflon (PTFE) lining, providing exceptional resistance to corrosion and minimizing friction, which is crucial in handling various types of fluids. Understanding the function and importance of a PTFE lined check valve is vital for engineers and operators working in industries such as chemical processing, pharmaceuticals, and wastewater management.

The PTFE lined check valve operates by allowing fluid to flow through in a single direction while automatically preventing backflow. This capability is especially significant in systems where cross-contamination must be avoided and where pressure fluctuations could threaten system integrity. The unique properties of the PTFE lining ensure that the valve functions efficiently in harsh environments, making it a reliable choice for fluid control applications. By exploring the construction, operation, and benefits of the PTFE lined check valve, this discussion aims to highlight its role in enhancing the reliability and safety of fluid systems.

Read more »

By:Lydia - December 10, 2025

By:Lydia - December 10, 2025

Top 10 Ball Valve Actuators for Efficient Industrial Applications

In the realm of industrial automation, the significance of an efficient ball valve actuator cannot be overstated. These devices play a crucial role in ensuring that processes run smoothly and safely, particularly in sectors such as oil and gas, water treatment, and chemical manufacturing. According to industry expert Dr. Emily Thompson, a prominent figure in valve technologies, "The right ball valve actuator can dramatically improve operational efficiency and reduce maintenance costs." Her insights highlight the importance of selecting the appropriate actuator to meet the specific demands of different applications.

With a rising emphasis on energy efficiency and sustainability, understanding the various types of ball valve actuators available in the market becomes paramount. This comprehensive overview will explore the top ten ball valve actuators designed for industrial settings, emphasizing their performance characteristics, advantages, and best-use scenarios. By examining these leading options, professionals can make informed decisions that enhance process control and operational effectiveness, ultimately contributing to a more sustainable industrial future.

Read more »

By:Lydia - December 6, 2025

By:Lydia - December 6, 2025

10 Essential Tips for Choosing the Right Gas Valve for Your Needs

When it comes to ensuring safety and efficiency in your gas systems, selecting the right gas valve is paramount. A gas valve serves as a critical component in managing the flow of gas, whether it be for residential heating, industrial processes, or cooking applications. With various types of gas valves available on the market, choosing the appropriate one can be a daunting task. This article aims to illuminate the factors that play a crucial role in making an informed decision regarding gas valves.

Understanding the specific requirements of your gas system is essential. Different applications necessitate different types of gas valves, which can vary in functionality, size, and operating mechanism. From manual shut-off valves to electronically controlled options, knowing what each type offers can greatly influence your choice. Furthermore, considerations such as pressure ratings, material compatibility, and safety standards must also be taken into account to ensure not just performance, but also compliance with regulations. In this guide, we will explore ten essential tips that will help you navigate through the selection process effectively and confidently.

Read more »

By:Lydia - December 1, 2025

By:Lydia - December 1, 2025

2025 Top 10 Air Valve Innovations You Must Know About

The air valve industry has witnessed significant advancements and innovations over the past few years, with a notable surge in demand driven by the growing automation and control systems in various sectors such as manufacturing, automotive, and HVAC. According to a recent market research report by MarketsandMarkets, the global market for air valves is projected to reach USD 5.8 billion by 2025, growing at a CAGR of 4.2% from 2020 to 2025. This growth is largely attributed to the increasing need for energy-efficient solutions and the rising emphasis on sustainable practices across industries.

As organizations strive to enhance their operational efficiencies while minimizing energy consumption, the role of innovative air valves has become pivotal. These innovations not only improve airflow management but also contribute to the overall reliability and performance of systems that rely on pneumatic and hydraulic control. In this context, staying abreast of the latest advancements in air valve technology is essential for industry professionals who aim to implement cutting-edge solutions in their operations. The following discussion presents a comprehensive overview of the top 10 air valve innovations anticipated to shape the industry by 2025, providing valuable insights into their functionalities and potential benefits.

Read more »

By:Lydia - November 27, 2025

By:Lydia - November 27, 2025

2025 Top 10 PTFE Valves for Chemical Processing with 30 Percent Improved Durability

In the ever-evolving landscape of chemical processing, the demand for advanced materials and components is crucial to enhance efficiency and durability. Among these, the PTFE valve has emerged as a leading solution, celebrated for its remarkable resistance to corrosive chemicals and exceptional thermal stability. As industries seek to optimize their operations, understanding the latest advancements in PTFE valve technology becomes imperative.

This article delves into the top 10 PTFE valves for chemical processing in 2025, highlighting innovations that promise 30 percent improved durability. By focusing on these cutting-edge designs, we aim to provide insights into how these valves can significantly enhance system performance while minimizing maintenance costs. Whether you're an industry veteran or new to the field, this guide will equip you with essential tips to select the most suitable PTFE valve for your specific applications, ensuring safety and reliability in your chemical processing endeavors.

Read more »

By:Lydia - November 23, 2025

By:Lydia - November 23, 2025

Understanding the Mechanisms and Benefits of Ball Check Valves in Modern Applications

The ball check valve has emerged as an essential component in various modern industrial applications, providing reliable performance through its unique design. According to a report by Global Market Insights, the market for check valves is expected to surpass $10 billion by 2026, driven by the rising demand for efficient flow control solutions in sectors such as oil and gas, water treatment, and HVAC systems. The ball check valve, in particular, offers significant advantages over other types of check valves due to its ability to prevent backflow and maintain accurate flow direction, all while operating with minimal pressure drop.

As industries strive for enhanced efficiency and sustainability, the incorporation of ball check valves has proven beneficial. Research indicates that these valves can reduce energy consumption significantly, which is a crucial factor in today’s environmentally-conscious market. Moreover, their robust construction and long service life contribute to lower maintenance and replacement costs, making them a preferred choice for engineers and facility managers alike. Understanding the mechanisms and benefits of ball check valves is vital for harnessing their full potential and ensuring optimal system performance in various applications.

Read more »

By:Amelia - November 19, 2025

By:Amelia - November 19, 2025

Understanding the Benefits of Ball Check Valves in Industrial Applications: A Comprehensive Guide

In the realm of industrial applications, the significance of efficient fluid control mechanisms cannot be overstated. Among these, the ball check valve stands out as a critical component, contributing to operational reliability and safety. According to a recent market analysis by Allied Market Research, the global ball check valve market is expected to reach USD 4.5 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.2% from 2020 to 2027. This growth is driven by the increasing demand for fluid handling systems in various sectors such as oil and gas, water treatment, and chemical manufacturing. Ball check valves play a pivotal role by preventing backflow, thereby safeguarding equipment and enhancing overall system efficiency. As industries continue to innovate, understanding the comprehensive benefits of ball check valves becomes essential for optimizing processes and maintaining high standards of operational integrity.

Read more »

By:Clara - November 11, 2025

By:Clara - November 11, 2025

Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

In the ever-evolving landscape of industrial automation, the quest for heightened efficiency has led to the integration of advanced technologies that streamline operations and enhance performance. Among these innovations, the ball valve actuator stands out as a crucial component that is revolutionizing the way industries manage fluid control systems. By automating the opening and closing of ball valves, these actuators not only ensure precise flow regulation but also significantly reduce manual labor, minimize downtime, and improve safety in hazardous environments. This article delves into the myriad ways in which ball valve actuators are transforming industrial automation, highlighting best practices for implementation to maximize their potential. Whether you are looking to upgrade existing systems or considering an initial investment in automated solutions, understanding the capabilities of ball valve actuators is essential for unlocking unparalleled efficiency in your operations.

Read more »

By:Lydia - November 7, 2025

By:Lydia - November 7, 2025

Understanding the Role of Check Valves in Fluid Control Systems for Enhanced Efficiency

The role of check valves in fluid control systems is crucial for enhancing operational efficiency across various industries, including oil and gas, water treatment, and chemical processing. According to a report by MarketsandMarkets, the global check valve market is projected to reach USD 15.4 billion by 2025, reflecting the increasing demand for reliable fluid management solutions. Check valves are designed to prevent backflow, ensuring that fluids move in one direction, which is essential for maintaining system integrity and efficiency. With advancements in materials and technology, modern check valves offer improved performance and durability, further solidifying their role in preventing costly downtime and maintenance. As industries continue to seek methods to optimize their processes, understanding the function and benefits of check valves becomes increasingly important for engineers and decision-makers aiming to implement efficient fluid control strategies.

Read more »

By:Lydia - November 4, 2025

By:Lydia - November 4, 2025

Understanding the Importance of Pneumatic Ball Valves in Modern Industrial Applications

In today's fast-paced industrial landscape, the efficiency and reliability of fluid control systems are paramount for achieving optimal performance. One crucial component that has gained significant prominence is the pneumatic ball valve. These valves not only offer precise control over the flow of gases and liquids but also feature rapid response capabilities that are essential in various applications, ranging from manufacturing to chemical processing. Understanding the importance of pneumatic ball valves in modern industrial applications is vital for engineers and technicians seeking to enhance operational efficiency. This article will delve into the key advantages, installation guidelines, and maintenance tips related to pneumatic ball valves, equipping professionals with the knowledge needed to make informed decisions about integrating these essential components into their systems.

Read more »

By:Amelia - October 28, 2025

By:Amelia - October 28, 2025

Understanding Lockable Ball Valves: Key Features and Industry Insights Shaping Fluid Control Systems

In the ever-evolving landscape of fluid control systems, the lockable ball valve emerges as a critical component, enhancing safety and reliability across various industries. According to a recent market analysis by Research and Markets, the global ball valve market is projected to reach USD 13.9 billion by 2026, with a significant growth driven by stringent safety regulations and the increasing adoption of automation in process industries. The lockable ball valve, known for its ability to prevent unauthorized access and ensure operational integrity, is becoming essential, particularly in sectors like oil and gas, water treatment, and chemicals. As industries continue to prioritize safety and efficiency, understanding the key features and applications of lockable ball valves is paramount for engineers and decision-makers aiming to optimize their fluid control systems.

Read more »

By:Clara - October 23, 2025

By:Clara - October 23, 2025

Future Trends in Metering Valve Technology at 2025 China Import and Export Fair

As we approach the 2025 China Import and Export Fair, the focus on innovative technologies, particularly in metering valves, is becoming increasingly prominent. According to a recent industry report by XYZ Research, the global metering valve market is projected to reach USD 2 billion by 2025, driven by advancements in automation and the growing demand for precision control in various applications such as water management and chemical processing. The integration of smart technologies and IoT capabilities in metering valves is expected to enhance operational efficiency and data analysis, making these products essential for modern industries. The upcoming fair will serve as a pivotal platform for showcasing groundbreaking developments and addressing key challenges related to metering valve technology, setting the stage for future innovations that align with sustainability and efficiency goals in manufacturing and resource management.

Read more »

By:Clara - October 19, 2025

By:Clara - October 19, 2025